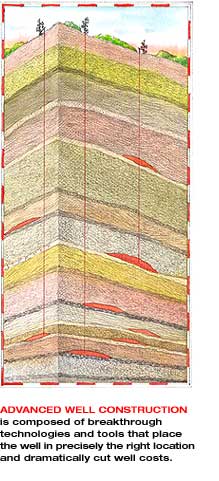

Well construction is the heart of the traditional energy services business. It encompasses drill bits, drilling, drilling fluids, cementing and formation evaluation. Advanced well construction includes the breakthrough technologies that will enable radically less expensive and more productive wells in environments such as deepwater. Halliburton’s Security DBS revolutionized its production process in 2000 for roller cone bits. Onsite engineers were empowered to modify standard designs to meet unique conditions and take the design directly to prototyping and manufacturing. The result is custom-designed bits in a third the time required by traditional methods. Besides the RESolution 3-D system already mentioned, Sperry-Sun introduced Geo-Pilot™ rotary steering system, developed jointly with Japan National Oil Corporation, as the industry’s first true point-the-bit rotary steerable drilling tool. The system produces clean, straight and smooth wellbores with less vibration. Minimum hole spiraling in turn improves hole cleaning, logging, and the quality of the cement jobs. Geo-Pilot enables precise, economical drilling of difficult well paths and will help push the limits of extended-reach drilling. Cementing and zonal isolation, a Halliburton strength since its founding, saw the release of the third version of OptiCem™ simulation system for designing optimum cementing operations, and OptiCem RT™ (Real Time), that allows onsite specialists to monitor a job in progress and make adjustments immediately. In addition, two new advanced pressure pumping units were introduced: Halliburton Precision,™ a single pump unit, and Halliburton Elite,™ a twin pump cementing trailer. These new units feature the RCM® IIE mixing system that ensures accurate mixing over a broad range of conditions, and ADC,™ the system that automatically controls slurry density throughout the job. Expandable tubing, a product of Halliburton’s Enventure partnership with Shell Technology Ventures, is an important technology that is extending the range of economical wells. Enventure expands the diameter of steel casings by as much as 25% after they are placed. This allows operators to work with smaller hole sizes, enabling them to drill deeper to reservoirs that were previously inaccessible. This capability is becoming increasingly important in deepwater developments.

A premiere breakthrough in this area for 2000 is the Anaconda Well Construction System. Anaconda will change the way wells are drilled, and provide operators with a new capability to find and develop isolated pockets of oil and gas. Anaconda is an innovative drilling system using carbon-fiber composite spoolable tubing, called SmartPipe.™ It includes conductors for two-way communication, and a downhole Advanced Drilling, Evaluation and Propulsion Tool (ADEPT) assembly. ADEPT sends enormous amounts of real-time information up the SmartPipe to the operators on the surface, who are then able to remotely direct the path of the well, allowing precise placement of the well bore within a given hydrocarbon zone. Anaconda wells will be guided using real-time updates of the earth model. They will bring together formation evaluation experts, drilling engineers, reservoir engineers, geologists and geophysicists to make instant drilling decisions. Anaconda can practically turn on a dime to probe for additional reserves or to access multiple reservoirs. The first commercial deployment is in the Gulf of Mexico, to be followed by work with Statoil in the North Sea. Statoil has been a partner in developing Anaconda over the last three years. |

||

Halliburton | Energy Services | Technology Flagships | Engineering & Construction | Financial Information | Corporate Information | Board of Directors | Printable Report © 2001 Halliburton Company |