The oilfield service industry’s research and engineering investment has developed evolutionary products that do things better and more cost effectively. But considering the rate of technology change in other industries, upstream technology can become more innovative and be developed more efficiently and much faster. The benefit to the customer will be lower cost for each barrel of oil or cubic meter of gas produced. To help accomplish this, Schlumberger is accelerating the pace of technology innovation through two strategic initiatives: the expansion of our network of innovation, and the successful six-year transformation of the Schlumberger research and engineering (R&E) organization.

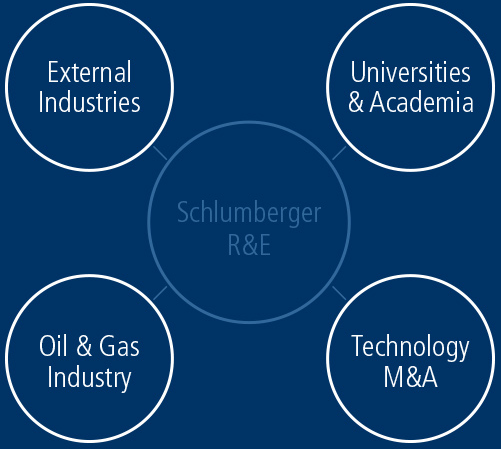

Expanding our network of innovation came from the realization that we do not have a monopoly on good ideas. Indeed many opportunities arise from combining external sources of innovation with our strong internal research and engineering capabilities. This is evident through our long-standing engagement with academia as well as with traditional Schlumberger customers and partners within the industry, an interaction that we are increasingly broadening to include leading companies from outside our industry.

We currently participate in more than 250 university collaborations in technical fields as varied as earth science, petroleum technology, information technology, software, cognitive science, and user interfaces.

A typical example of oilfield innovation comes from our collaboration on magnetic resonance imaging (MRI) with the University of Cambridge, UK, and Massachusetts General Hospital in Boston. The application of MRI to the oilfield is not new—wireline logging tools have used the technique for more than 30 years. But a new approach is the application of MRI to image oil recovery with a bench-top system using methods developed over multiyear projects with the university, making it possible to acquire images in only 20 minutes from rock core-plug samples flooded with brine. At the same time, we discovered that techniques that we developed for the oil field can enhance medical scan interpretation in the hospital. Given that the origin of oilfield MRI was the medical world, this is a remarkable example of the information exchange from medicine to oil and gas and back to medicine.

Collaborations such as these stem from Schlumberger actively establishing and maintaining close relationships with leading universities over the past 30 years. To further develop these relationships, Schlumberger has located research laboratories as close as possible to universities as widespread as the US, Brazil, Russia, Saudi Arabia, and China.

One of our unique strengths is the ability to identify the right merger and acquisition (M&A) targets, close them in a timely manner, and then successfully integrate them into Schlumberger—while leveraging the process as a source of innovation. Our M&A activity ranges from large acquisitions such as Smith International to early-phase investment in small start-ups. Over more than 20 years, we have established a track record of successful acquisitions that have increased technology offerings, expanded markets, and built product-line leadership. While it is evident that M&A activity adds scale, its main objective is to bring customers the most complete range of innovative technology and services.

The development of market-leading Stinger* conical diamond element drillbit technology exemplifies this approach. The acquisitions of Novadrill as a disruptive technology, Lyng Drilling as a specialist manufacturer, and Smith International as a leading drillbit supplier—backed by the strength and expertise of the Schlumberger R&E organization—led to the successful introduction of innovative bits incorporating the Stinger element in 2012. The latest generation of StingBlade* conical diamond element bits, launched in mid-2014, not only increases footage drilled and rate of penetration but also improves steerability and directional control.

See how the StingBlade bit’s unique placement of polycrystalline diamond compact (PDC) cutters overcomes the challenges of nearly any formation.

Learn MoreTechnology collaboration with major customers is another driver of innovation. Our customers bring real-world value to projects through their depth of experience and understanding of E&P challenges. By combining resources and expertise, we can address major industry challenges such as effective field development in basins of greater complexity than in the past. Today, we have technology collaborations with each of our top-10 customers.

The recent introduction of the Schlumberger INTERSECT* high-resolution reservoir simulator shows how successful collaboration breeds innovation. Backed by Chevron and Total, the new simulator took more than 10 years of development before its commercial launch. Leading experts in reservoir characterization, numerical modeling, applied mathematics, and high-performance computing as well as staff from Stanford and Oxford Universities contributed to the effort. Since its commercialization, the INTERSECT simulator has been used to model and manage 120 of the most challenging oil and gas fields in the world. INTERSECT simulator technology has significantly improved subsurface modeling and understanding for optimizing field development production strategies in complex reservoirs.

The size and depth of our portfolio also offer opportunities for innovation through collaboration with other industrial companies that pursue new technology as keenly as Schlumberger. For the last seven years, for example, Schlumberger has worked with nVidia and Stanford University on the high-performance computing techniques that are essential to the success of advanced seismic acquisition systems. In France, home to Saint-Gobain, the world’s largest manufacturer of crystal glass, a recent project focused on the joint development of new large-scale crystals for industrial applications. This technology is used by the Wireline product line’s Litho Scanner* high-definition spectroscopy service—the first logging tool to noninvasively measure the total organic content of shale reservoirs downhole. This parameter is of vital importance in estimating the hydrocarbon potential of such unconventional resources.

Another example comes from the Schlumberger commitment to lead the adoption of industrial applications of the Google Glass wearable platform. This technology facilitates access to information and knowledge for personnel engaged in equipment maintenance and calibration as well as in field operations so they can perform their tasks as efficiently and effectively as possible. Across our R&E organization, Schlumberger is engaged with more than 150 technology partners, all of which add to the rich global network of innovation we have built around the world and across academia, customers, and industries.

See how the Quanta Geo photorealistic reservoir geology service lowers finding and development costs by generating detailed images of rock formations.

Learn More

Realizing the full benefit of accelerating the flow of innovative ideas largely depends on how effectively an R&E organization can translate them into high-performance, field-ready technologies. To ensure that we achieve this strategic advantage, we have transformed both the efficiency and quality of the Schlumberger R&E organization. This massive undertaking—costing the company an estimated $350 million—started six years ago with the benchmarking of existing R&E processes against leading companies in other industries, followed by a complete restructuring of the organization, and finally the development and implementation of a new R&E operational system.

See how the BroadBand* unconventional reservoir completion services deliver improvements in production and recovery for our customers.

Click Here to Learn About BroadBand SequenceThe new system was developed through the concerted effort of hundreds of R&E professionals who worked on rewriting the fundamental processes used to develop and manufacture Schlumberger products. We built on our traditional strengths of innovation, science, and technology and complemented these with modern approaches successfully deployed by leading companies in the automotive and aerospace industries. The new R&E system achieves three ambitions: by emphasizing efficient product development methodologies and product industrialization, we have reduced cycle time from the idea stage to the mature product, supported our accelerating rate of innovation, and reduced new product time to market. In addition, we have also set a clear goal to make a step change in the reliability of our technologies, with a particular emphasis on their out-of-the-box performance. This is perhaps the most critical element of our R&E transformation.