In North America, the expansion of unconventional resource development has benefitted from adopting technologies and processes, such as multistage completions, to improve operational efficiency and reduce operating costs. Furthermore, the integration of best-in-class hydraulic fracturing, multistage completions, and pumpdown perforating technologies is leading to increased operational efficiency and improved long-term reservoir management.

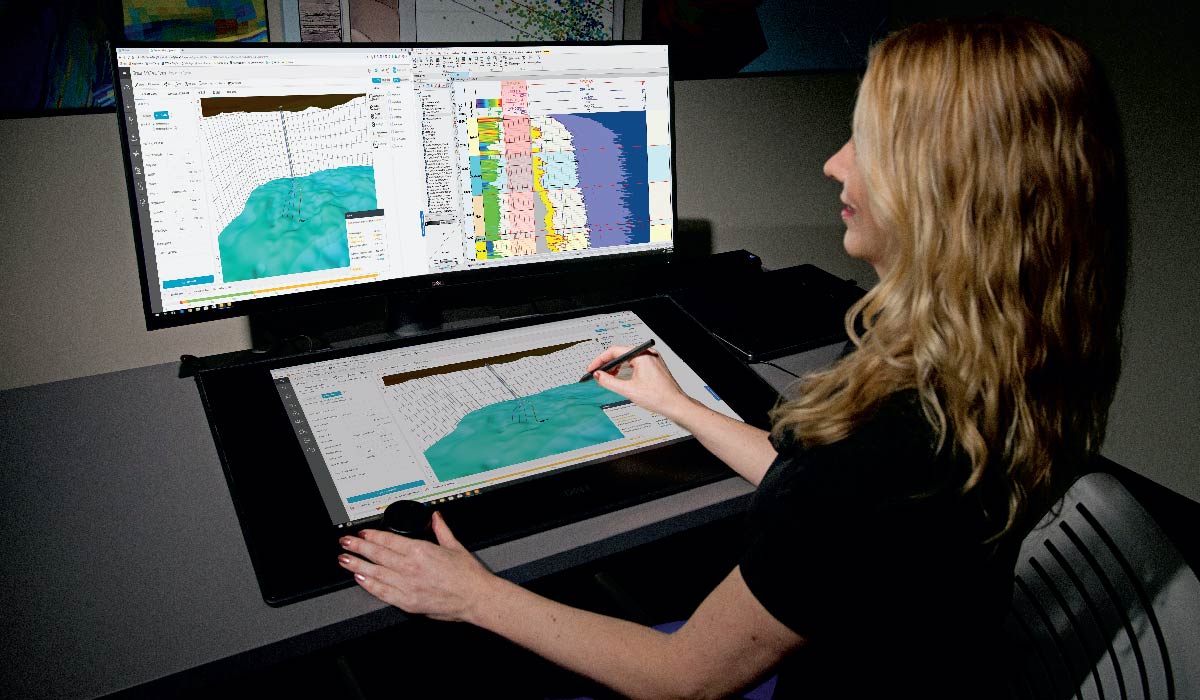

The OneStim® integrated completions system brings domain experts together in state-of-the-art facilities to align every aspect of the well completions process, from operational planning to resource management. These fully integrated services start with mining, delivering, and managing proppant at the wellsite. The unique vertical integration of sand mines, trucking, and an extensive rail network ensure on-time delivery of proppant to Schlumberger North American operations, optimizing logistics and fleet utilization.

In the Eagle Ford Shale, OneStim helped a customer decrease pad-to-pad mobilization by 50% and more than double the amount of stages placed per day. Integrating technologies such as the CAMShale* fracturing fluid delivery and flowback service reduced rig-up time—from three hours to less than 18 minutes. The number of connections needed was similarly greatly reduced by using Monoline* flanged-connection fracturing fluid delivery technology to conduct single-line rig-up.

Our hydraulic fracturing technologies are helping operators complete more stages per day and optimize reservoir stimulation. In unconventional reservoirs, parent wells are initially drilled and subsequently followed by child, or infill, wells. As subsurface dynamics change between parent and child wells, BroadBand Shield* fracture-geometry control service and WellWatcher Stim* stimulation monitoring service make it possible to maintain the productivity of existing wells while avoiding detrimental parent-child well interactions. For a customer in North Dakota, BroadBand Shield service helped overcome such an interaction during the stimulation of a child well, saving approximately $400,000 in intervention costs and more than two weeks of deferred production in neighboring parent wells.

Through vertical integration of sand supply via mining, logistics, and pumping services as well as its streamlined management of resources and operations, the OneStim system enables efficiencies that result in greater cost savings. Our novel fluid and proppant technologies can also decrease the water and sand requirements for each well. On average, the HiWAY* flow-channel fracturing technique uses 40% less proppant in hydraulic fracturing treatments. Compared with slickwater treatments, the HiWAY technique uses 25% less water, decreasing the environmental impacts at the wellsite.

The environmental impacts of well completions operations can be reduced even further by using the Schlumberger Stewardship Tool. This innovative software can evaluate every phase of a well completions project by managing risk, mitigating pollution, minimizing waste, and lowering greenhouse gas emissions, among other considerations. The tool provides quantitative results based on specific job information, from the type of wellsite equipment needed and how it is powered, to water and chemical usage. The Stewardship Tool can assess 19 key performance indicators, which are aligned with the Global Reporting Initiative, an independent international standards organization, in its G4 Sustainability Reporting Guidelines.