|

H

E X C E L M A R K E T S Hexcel has been taking the lead in efforts to identify new applications for new materials and cost effective processes in advanced structural materials. Developing such new applications, in fact, is an important driver of future growth for the company. |

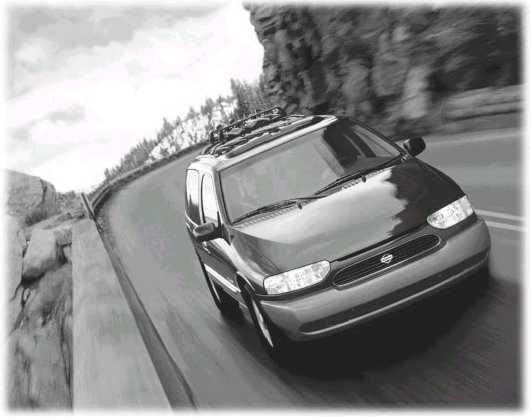

The Nissan Quest minivan uses Hexcel honeycomb to help reduce critical head injuries in collisions.

|

|

|

|

|

Total 1998 Pro Forma Hexcel Sales: $1,235 million Total 1998 Pro Forma General Industrial Sales: $163 million, or 13% |

TRUCK FLOORS: One-piece cab floors for Kenworth T2000 trucks are produced by Hexcel using a unique injection pultrusion process. These lightweight panels offer superior performance and less assembly time than traditional steel floors. |

HIGH-SPEED TRAINS: Hexcel’s new fire-resistant, low temperature curing M34 prepreg was used to build the driver’s cab of the new VT 612 train from Adtranz. |

HIGH-SPEED FERRIES: Hexlite panels are used in the interiors of many high-speed ferries and ships. The superior stiffness and low weight of the panels provides design flexibility and rapid installation. |

IT WAS THE AEROSPACE industry that first recognized the value and benefits of advanced structural materials. In the years during and after World War II, first military aerospace and later commercial aerospace were transformed by lightweight, high strength materials manufactured by Hexcel and others.

A Fu t u r e R e v e n u e S o u r c e

Today commercial and military aerospace continue to be important markets for Hexcel, and that is not likely to change in the foreseeable future. However, many other major industries throughout the world are experimenting with advanced structural materials. While many of these new applications may take time to develop, they represent a future revenue source with enormous potential.

Hexcel has been taking the lead in efforts to identify new applications and expand existing applications for our materials outside aerospace. We are also focused on developing and commercializing new, lower-cost processes for making advanced structural materials and parts from these materials. These efforts are an important driver for the company’s future growth. To that end, Hexcel Ventures was created in late 1997 to bring together research and technology, engineering, manufacturing and marketing resources to pursue selected longer term opportunities in these areas that would complement the numerous programs being pursued in the global business units.

M a r k e t s w i t h A t t r a c t i v e P o t e n t i a l

Among the markets that offer attractive potential for increased use of advanced structural materials:

- Surface transportation, including high-speed and mass transit trains, high-speed ferries and other marine vessels, autos and trucks. During 1998, we delivered our 10,000th composite floor for the Kenworth T2000 brand of long-haul trucks.

- Automotive applications. The makers of the popular Nissan Quest minivan are using Hexcel’s new energy-absorbing honeycomb technology to enhance passenger safety. Hexcel components are installed in the headliner section of the van, where a person’s head could make contact in an impact. Nissan’s choice of Hexcel honeycomb as the most efficient solution will ensure compliance with a new US safety regulation and help reduce critical head injuries in collisions.

- Civil engineering and construction. During 1998, Hexcel established a global strategic alliance with Sika Finanz AG, a worldwide leader in construction chemicals and structural adhesives, to develop and market composite systems to the construction industry. Initial applications focus on projects involving the strengthening and repair of existing structures using composite materials. Hexcel takes leadership for the development and manufacture of advanced structural materials for the alliance, while Sika leads the marketing and sales efforts.

- Uses for structural fabrics that go beyond fiberglass electronic materials. These include decorative and architectural fabrics and soft body armor.

- Wind energy blades, a market that is quite active in Europe.

|

|

|

|

|

WIND ENERGY: Wind power technology requires large wind generator blades capable of withstanding harsh climactic conditions for long periods of time. Demand for increasingly larger wind turbine blades to produce greater energy output is creating a developing market of low weight structural composite materials. |

WINDOW BLINDS: Hexcel’s specialty fiberglass fabrics provide the

ideal insulation solution for windows and other interior decorating

dilemmas. Hexcel blind and screen fabrics are washable, durable

and available in hundreds of colors and patterns.

|

SEISMIC RETROFIT: Hexcel’s civil engineering and construction systems for buildings and other structures are cost competitive, are easy to install and offer attractive repair, strengthening and earthquake protection features. |

SOFT BODY ARMOR: Aramid fabrics are found in bullet, fragment and stab resistant soft body armor used worldwide. Hexcel’s Hexguard ® fabric is used in retrofitted door and ceiling panels of VIP vehicles. |