|

|

|

|

|

|

SERVING CUSTOMERS AND SUPPLIERS

THEN AND NOW

|

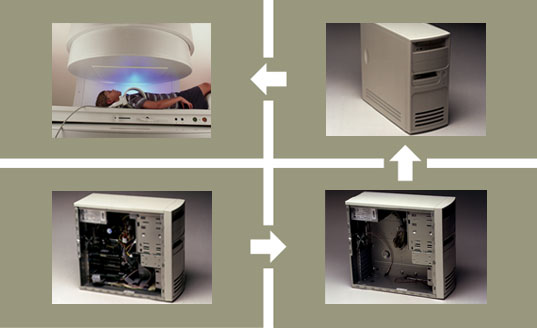

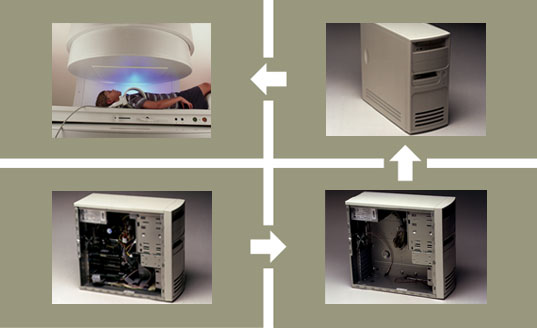

Since the late 1960s, advances in electronic technology have led to the manufacture of a wide array of products, ranging from the microwave oven to complex satellite systems. Arrow´s suppliers have developed the key devices that drive technology, and Arrow´s customers have used that technology to create the products that are now an integral part of our daily lives. Since the first microprocessor was launched in the early 1970s to the mid-1980s, when electronics manufacturing became the largest manufacturing industry in the United States, electronic technology has replaced much of what was once manual or mechanical. Electronic controls for industrial machines have led to dramatic improvements in productivity and quality. Medical imaging systems facilitate the early detection of diseases. Advances in telecommunications have connected people to information and to each other across the globe.

Throughout the evolution of new technologies, Arrow Electronics has been a pivotal intermediary between the manufacturers of components and computer products and the customers who use those products to design and manufacture electronic products and systems. As the industry has evolved, so have the solutions that Arrow offers. In the early 1970s, the main role of electronic components distribution was inventory management for customers and sales support for suppliers at the local level. With the computing and electronics boom of the 1980s, demand for just-in-time delivery of parts increased, as did the demand for products outside of the North American market. In 1985, Arrow was the first North American electronic components distributor to establish a presence outside of the Americas. In the 1990s, the faster pace of new product launches and shorter product life cycles increased the need for materials management and physical value-added services. As the industry entered the new millennium, complex information needs, sophisticated supply chain management strategies, and new approaches to manufacturing drove greater demand for products and services at every point of a customer´s product life cycle.

|

ACROSS THE SUPPLY CHAIN

|

|

Arrow Electronics has led the industry in developing solutions to power the electronics manufacturing supply chain. One powerful example of a "design-to-delivery" solution is the growth of systems integration and configuration services offered by Arrow´s North American Computer Products group (NACP). Today, Arrow is managing almost every aspect of the supply chain for several large OEMs. A typical solutions model starts from the moment the OEM receives an order from its end-customer and immediately transmits that order to Arrow´s system. Arrow´s materials planning programs have anticipated the order, and have all the necessary computer products, components, and system enclosures in inventory and ready for the build. The Arrow computing solutions integration team then configures and tests the system, shipping the completed product to the OEM´s end-customer anywhere in the world. The OEM designing and selling the system essentially owns the completed product for only a matter of minutes just prior to shipment. Arrow may also collect payment for the system on behalf of the OEM. On average, Arrow NACP builds and ships in excess of 10,000 sub-systems and completed systems each month for OEMs in a wide range of technology industries. |

ANYWHERE IN THE WORLD

|

Since 1985, Arrow has led the industry in global expansion, and Arrow now has more than 200 sales locations and distribution centers in 40 countries and territories to serve customers and suppliers according to local practices, languages, and customs. Today, the emergence of large global manufacturers has made it possible for customers to design and develop products in one region, and move production to another region of the world. These cross-market customers require integrated support across regions, as well as local support in design and production markets.

In no other region is this manufacturing migration more evident than in Asia/Pacific. This region is now the world´s largest and fastest-growing electronics manufacturing market, a market that accounts for close to 40 percent of the more than $200 billion in components purchasing worldwide. Much of this volume comes from cross-market customers moving production to the region. This trend is not limited to the Asia/Pacific market alone, and to respond to the growing need for cross-market solutions, Arrow launched the Global Business Conversion group (GBC). Arrow GBC receives advance information from local sales teams when customers plan to transfer production to other markets. This group works closely with the Arrow teams and the suppliers in the production markets to quote and win business, and to coordinate the inventory resources and logistics services required. With the combination of Arrow´s local sales teams across the globe and the GBC team, Arrow stands ready to support the distribution needs of customers and suppliers anywhere in the world where they choose to do business. |

WITH THE RIGHT PEOPLE AND PROCESSES

|

Arrow provides the power for the electronics and computing manufacturing supply chain, and Arrow´s people provide the power that delivers products and services to more than 150,000 customers and 600 suppliers around the globe. Arrow has the most experienced senior leadership team in electronic components distribution, with each major region led by an executive with an average of more than twenty years tenure in the industry. The depth of talent goes beyond the senior level, with employees who are expert in the technologies and the complex supply chain solutions that speed customers' time to market. Around the world, Arrow employees use their talents to create new solutions and to deliver each day the personalized service that customers and suppliers have come to expect.

An expanded presence across the supply chain has increased the complexity of delivering solutions to customers and suppliers. Today, Arrow is increasingly called upon to do work that customers and suppliers historically did themselves. As a result, while sales have declined by close to 40 percent from the peak in 2000, daily transactions have only declined by an average of 25 percent. To remain profitable in this environment, Arrow has focused on process improvements that make it possible to respond to changing customer and supplier requirements with increased efficiency. Efficient management of working capital, costs, and processes has helped the company generate more than $2.2 billion in free cash flow since the first quarter of 2001. As Arrow enters 2003, the company is well-positioned to respond to the changing needs of customers and suppliers. |

READY FOR THE FUTURE

|

Everyday life has been transformed, and will be transformed again, by technology. New technologies and applications will place greater demand on customers and suppliers for innovation and speed. Arrow provides the power for this dynamic and ever-changing supply chain, with the products and services that bring new technological solutions to market faster and more efficiently.

|

|

|

|

|

|

|

|

|

|

|

|

| Back to Top |

|

|

|