Clean air and pure water

The work we do to protect the environment, to preserve our natural resources and to ensure the safety of our employees is a fundamental part of our culture. We consistently look for new and innovative ways to reduce our impact on the environment.

Emissions Inventory

Since 1990, we have been reducing our greenhouse gas emissions through a growing number of new technologies and innovations. We have spread our efforts across the United States and Canada, surpassing milestones and winning recognition from industry and government partnerships. We reached another important stage of our program in 2007 with development of a monitoring system that allows us to track methane and carbon dioxide emissions from production facilities companywide.

The inventory is a useful tool in our ongoing effort to cut carbon dioxide emissions and to keep methane in the pipeline and available for sale. Using this system, we can evaluate our operations and identify opportunities for reductions. With this information we can determine the most effective locations to deploy emissions reduction technologies such as the installation of vapor recovery units on tank batteries, or the use of modern, low emission valves at well sites, pipelines and compressor stations.

In 2007, we inventoried our annual carbon dioxide emissions from Devon's U.S. operations. Factored against production, our emissions intensity was at or below that of other large North American oil and natural gas producers. Through the inventory we can document reduction in emissions intensity, track our progress, set goals and disclose results to stakeholders.

As concern over climate change issues continues to build, we expect ongoing progress and believe our inventory gives us a solid foundation from which to measure future progress.

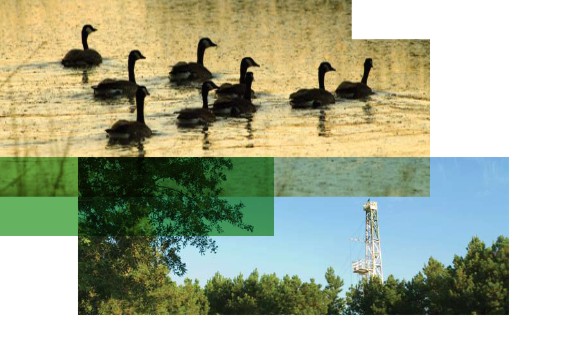

We have recycled more than five million barrels of water utilizing units such as this in the Barnett Shale field in north Texas.

Water Recycling

Part of what we do as an environmental steward is look for opportunities to conserve our natural resources. Our pioneering effort to recycle water in north Texas is an example of how innovation can benefit the environment and surrounding communities.

The Barnett Shale surrounding Fort Worth is the fastest-growing natural gas field in the nation, producing more than three billion cubic feet of gas per day from a geological formation that extends over 5,000 square miles. However, shale gas is an unconventional resource requiring large amounts of fresh water to stimulate production.

In 2005, we began a recycling program to reclaim water used to stimulate our natural gas wells. We use heat to vaporize waste water recovered from the wells, then condense the steam into distilled water to be reused in other well stimulation projects. Since establishing the program, we have recycled more than five million barrels of water.

Each year, the volume of water we recycle grows. Our program began with two recycling units in 2005. Today the recycling effort has expanded to nine units in the Barnett. The units operate around the clock and each one processes more than 2,500 barrels of water a day.

While we are excited about pioneering water recycling in the Barnett Shale, we are not finished. We continue to enhance the efficiency and economics of recycling to establish new opportunities in other areas where we operate.