Safety and Wellness

For a Healthy, Productive Workforce

-

OSHA’s Voluntary Protection Program (VPP) uses rigorous criteria to recognize worksites with exemplary safety programs. Raytheon’s comprehensive EHS audit program provides a strong foundation for our operating locations to receive VPP certification. In 2009, six Raytheon sites achieved VPP certification. At recent certification ceremonies, OSHA coordinators visited our Sudbury, Mass. facility and Lemmon Avenue facility in Dallas, Texas. Raytheon now has 10 VPP Star certified locations.

-

Raytheon’s focus on employee safety and wellness demonstrates our strong commitment to corporate responsibility. The immediate goal of our safety and wellness programs is to protect our people. Ultimately, we seek to improve the quality of life enjoyed by all members of the Raytheon community. Benchmark data, performance metrics, and external recognition all indicate that we are succeeding.

OSHA Voluntary Protection Program

In 2008, we established the long-term sustainability goal of attaining OSHA Voluntary Protection Program (VPP) certification at our major domestic sites by 2013. OSHA’s VPP uses rigorous criteria to recognize worksites with exemplary safety programs. Only 2,314 of approximately nine million worksites in the U.S. have achieved VPP certification. Our safety programs and comprehensive Environmental, Health and Safety (EHS) audit program create a strong foundation for Raytheon’s operating locations to achieve VPP certification. In 2009, we achieved OSHA VPP certification at six sites: Andover, Mass.; Sudbury, Mass.; Tewksbury, Mass.; White Sands Missile Range, New Mexico; Lemmon Avenue in Dallas, Texas; and Norfolk, Va. We now have 10 VPP Star certified locations.

-

Injury Prevention

Achieving an injury-free workplace is a priority at all levels of the company. During 2009, Raytheon Chairman and CEO William H. Swanson convened a Strategic Safety Dialogue that was attended by 50 leaders representing each of Raytheon’s six businesses. The group shared best practices and had an open, constructive dialogue to develop ideas to improve our safety performance.

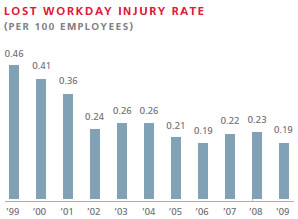

In moving toward our ultimate goal of an injury-free workplace, Raytheon tracks three OSHA performance measures: recordable injury rate; lost workday case rate; and Days Away/Restricted or Transferred Rate (DART). Raytheon has made significant progress by implementing best-in-class safety programs and processes. The 2009 injury rates were the lowest ever achieved at Raytheon. In 2009, our recordable injury rate decreased 11% from 0.79 to 0.70 (from 592 injuries to 537 injuries) and our lost workday injury rate decreased 17% from 0.23 to 0.19 (from 173 injuries to 142 injuries). Beginning in 2009, we reported our DART Rate. Our 2009 DART Rate was 0.33, representing 256 DART cases. Since 1999, Raytheon has reduced its OSHA recordable injury rate by 66% and its lost workday injury rate by 59%.

-

Workers' Compensation Program

Raytheon continues to be an industry leader in workers’ compensation programs, utilizing many innovative tools effectively to manage and minimize the cost of employee absence. As we strive to reach an injury-free workplace, the proactive Raytheon Loss Prevention program continues to be a key component in all aspects of our business. When an injury occurs, Raytheon consistently seeks the best possible treatment for its employees. We prioritize an early and safe return to a productive work setting whenever possible. Raytheon consistently exceeds industry benchmarks relative to workers’ compensation metrics. Most recently, our average workers’ compensation claims cost per employee was approximately $64.00, against an industry average of $403.00.

-

Leading Injury Causes

The two leading causes of injury continue to be ergonomics and slips, trips and falls. We define ergonomic injuries broadly to include not only repetitive motion injuries, but any injuries that involve pushing, pulling, lifting or lowering. Material handling injuries are one of the most common types of ergonomic injuries. In 2009, we developed and deployed two Web-based learning modules to address lifting risks and slips, trips and falls. The modules are now being deployed to our focus area of touch labor employees. We are also working with our unionized workforce to address and reduce injuries more prevalent within this part of our employee base. Across the company, we continue to resolve risks identified in assessments and are tracking mitigation measures to completion with the oversight of senior management and the Board of Directors.

Safety Awards

Raytheon Chairman and CEO William H. Swanson was recognized by the National Safety Council® as one of the CEOs Who ‘Get It’ for his outstanding safety leadership. The Aerospace Industries Association (AIA) awarded Raytheon its 2009 Worker Safety Excellence Award in the Missiles and Space category based upon having the lowest injury rate and an exemplary safety program. OSHA awarded Raytheon its Region 1 Administrator’s Award for extraordinary contribution to the success of the Voluntary Protection Program (VPP).

-

Environmental, Health & Safety Audits

Raytheon’s robust Environmental, Health & Safety (EHS) internal audit program performs an average of 25 audits per year to assess compliance with governmental and company requirements. Sites are assessed on five established protocols: safety; industrial hygiene; environmental; asset protection; and EHS management systems. Locations are prioritized for audits based upon risk and the complexity of their operations. Audit results are reported up through the business presidents and to the CEO.

Ensuring Compliance

One indicator we use to measure the effectiveness of our audit program is our compliance record with regulators. Our responsibility is to ensure full compliance with all environmental, health and safety laws and regulations, as well as internal Raytheon policies and standards. In 2009, federal, state and local regulatory agencies conducted 128 environmental and safety inspections of Raytheon operating locations. Nine notices of violations (NOVs) were issued — three related to environmental issues and six to safety issues. Two resulted in fines totaling $1,600 related to powered industrial truck safety and a hazardous material business plan. We perform a thorough root-cause analysis for each NOV and share "lessons learned" across the company to prevent recurrence.

-

Mission:Health

Through Mission:Health, Raytheon’s health engagement strategy, the company offers comprehensive health and wellness programs, services and resources to employees and their families, encouraging them to adopt and maintain healthy lifestyles. We strive to provide a culture that supports employee health through fitness programs, healthy eating choices, health screenings, and preventive health programs and resources.

In 2009, employee health screenings were added to the wellness program offerings. The screenings included blood pressure, cholesterol, blood sugar, height, weight, body mass index and health coaching. Through this program, employees identified as being at high-risk received coaching on how to improve their health, and many were referred to the disease management programs provided by their health plan for additional support in improving their health.

-

Wellness programs are also offered internationally. A tobacco cessation program, an online health management tool provided by WebMD® and associated programs, became available to our international employees and their families. We also established a companywide Pandemic Task Force to protect the health of our employees and ensure business continuity in the face of pandemic outbreaks such as the H1N1 virus.

Raytheon was honored in 2009 by the National Business Group on Health with a Best Employers for Healthy Lifestyles Gold Award, recognizing our efforts to help employees and their families make better choices about their health and well-being.

-

Work/Life Program

Raytheon provides a number of customized programs and services to help employees and their families cope with the everyday and out-of-the ordinary stresses that can affect health and productivity.

The Work/Life Program is designed to meet the needs of a diverse workforce. In 2009, Raytheon introduced a series of podcasts as an alternate communication vehicle, designed to educate employees about the many work/life services and programs available to them including:

- Integrated Employee Assistance Program and resource and referral programs;

- Back-Up Care Advantage Program, providing child and adult care to employees when their usual care arrangements are unavailable;

- Enhanced eldercare program that provides in-home assessment, evaluation and recommendations for elder family members;

- Flexible work arrangements to maximize work/life effectiveness for employees;

- Financial counseling services;

- Group legal plan offering access to a nationwide network of attorneys who can help with a variety of legal matters; and

- Estate planning for special needs dependents.

-

Raytheon’s Integrated Disability Programs, Global Health Resources and EHS joined forces in 2009 to introduce a series of webinars and safety resources focused on keeping employees and their families safe outside of work, as well as on the job. The first webinar educated employees about ladder safety. Fractures are the number one injury within our population, with one-third of all short-term disability claims related to musculoskeletal injuries such as fractures, sprains and dislocations. By educating employees on the simple steps they can take to stay safe off the job, we’re helping them to stay on the job, and stay healthy.