| NEXT |

|

|

|

|

|

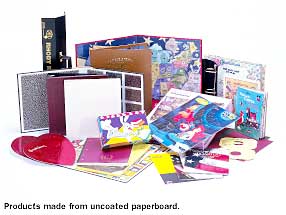

The Mill Group supplied nearly 250 thousand tons of uncoated recycled paperboard from six mills to Caraustar’s Industrial & Consumer Products Group during the year. Successful co-development projects, such as the manufacture of a high-strength, cost-effective core for the carpet industry by the Austell and Chattanooga mills, and the development of a superior film core paperboard by the Reading mill, demonstrate Caraustar’s ability to integrate technical resources across divisions to meet customer needs. Additionally, by taking advantage of the strong relationship between the Mill Group and the Industrial & Consumer Products Group, the mills can provide value to their independent customers, providing the technical expertise in adhesives, tube winder design, and equipment operation. The specialty paperboard mills and converted products plants manufacture and laminate paperboard for end uses such as puzzles, game boards, picture frame backs and easels, coin folders, mat boards and book cover boards. Early in the year, Caraustar’s Carolina Converting, Inc. met a significant supply challenge by providing millions of coin folders and maps, using a specialized paperboard, CaraM, manufactured at our Carotell Paper Board mill and converting operation. The strong relationship between the mills and converting plants provides Caraustar with an effective method for taking advantage of new product and market opportunities.

Multiple mill locations and improved machine technologies allow the Mill Group to provide a full range of clay coated recycled products. The coated paperboard mills manufacture recognized 100 percent recycled products under the tradenames of Inverkote™ and Britone™. These grades of paperboard are used for a broad range of folding carton needs, including packaging for pasta, candy, powdered detergents and cracker products. Specialty products such as Whitone, Statone™ and Kraftone are designed as alternatives to solid bleached sulfate and other virgin fiber substrates and can be customized to meet more specialized packaging for medicinal, candy, pet food and other types of custom packaging needs. Caraustar’s coated mills provide approximately 400 thousand tons of recycled paperboard to the market, a portion of which is used by the Caraustar Custom Packaging Group. In addition, our coated mills are the leading supplier of coated paperboard to independent folding carton manufacturers. |

During 2000, the Mill Group invested capital in key technical areas, such as recovered fiber processing systems, designed to provide clean, consistent product to its customers at a competitive price. The Sprague, CT mill recovered fiber processing system was rebuilt in June 2000, further reducing the dependency on high cost fiber. Similar systems installed at both the Rittman and Tama mills continue our focus on reducing recycled fiber processing costs while improving product quality and uniformity. The Mill Group operates with a decentralized organizational structure, which locates both our decision-makers and service capabilities within close geographic proximity of our customers. This strong local management commitment to understanding and satisfying our customers’ needs and providing innovative products keeps Caraustar mills at the forefront of the markets they serve.

|

|

9 |

|

| NEXT |

|