Our transformation advantage stems from our mature matrix organization structure, which was established in 1998 with the creation of GeoMarket geographical regions with comparable geological markets. This is enhanced by our identity as a technology company with a common culture for excellence that is aligned with our customers. As engineers, we speak our customers’ language and are able to develop the technology and business models they need to improve their performance.

By focusing on resource management and exceeding our own standards for service quality, we are addressing the things under our own control.

The transformation program would not have been possible without executive management’s commitment to new technology and a long-term perspective of the business that does not waver in response to market fluctuations. Executive management and the heads of every department are members of the transformation board and report directly to the Chairman and CEO. This means that executive management is accountable for the transformation program’s development, enablement, and deployment. In turn, they lead a cohesive team of line and functional managers who use a top-down approach to implement a step change in performance by focusing on technology, reliability, efficiency, and integration.

The depth and breadth of the Schlumberger transformation is unparalleled by any other company in the oil and gas services industry. The first eight years of our transformation journey have established a new product development method as well as a new process for Technology Lifecycle Management. In addition, our Shared Services Organization combined seven functions to leverage our size in order to facilitate profitable growth and manage business cycles more efficiently.

The transformation program focuses on the delivery of new technologies and business models that involve greater integration. As our customers’ resources become stretched and they seek new ways of working, the adoption rate for integrated services is increasing. Involving customers early in the integration process is a key consideration. We must now use integrated workflows to meet challenges, such as subsurface risk during exploration and increasing ultimate recovery at the end of a reservoir’s productive life. Increased levels of integration will enable us to optimize production while reducing cost per barrel.

One example that illustrates how integration brings value to our customers is the Det norske Ivar Aasen project in the North Sea. Working far ahead of the project start date, we adopted a unique collaboration model where Det norske and Schlumberger project teams are collocated. This makes it easier to integrate services and optimize the resources required between the rig, the shore base, and a remote operations center. The highly efficient approach to staffing levels includes remote operations, multiskilling, and new fit-for-purpose technologies.

Discovered in 2008 by Det norske, the Ivar Aasen field offshore Norway sits below 112 meters of water in the North Sea and contains approximately 210 million barrels of oil equivalent. In 2014, Schlumberger signed a five-year integrated services contract with Det norske, making Schlumberger an integral part of the well construction process with incentives to deliver the maximum gain through technology innovation, reliability, efficiency, and integration.

A combination of detailed project management and resource planning as well as experienced personnel ensured the optimization of resources between the offshore rig, the shore base in Trondheim, and the remote operations center in Stavanger. We created a dedicated project organization that assigned human resources with the skills to deploy the best available technology through established workflows and processes.

For example, StingBlade* conical diamond element bit technology contributed to an improved rate of penetration due to its reliability and wear resistance under severe shock and vibration. In addition, GeoSphere* reservoir mapping-while-drilling service geologically steered four horizontal well sections more than 2,000 meters in length and helped delineate layers in the reservoir at distances in excess of 30 meters.

This integrated services project resulted in the drilling and completion of five wells among the top 10 best performers in the last eight years on the Norwegian Continental Shelf. On one of the wells the total operational savings due to the integrated approach, which was backed by our transformation, halved the time needed to drill and complete the well compared with the planned budget.

Our management system defines the corporate boundaries within which the company operates. We control corporate risks by leveraging our global experience to define the controls used to manage risks and enhance decision making. This is manifested by our business governance structure.

The management system is a fundamental pillar for the new ways of working we are implementing. Our corporate identity is underpinned by The Blue Print, the highest level of our governance structure, which establishes our purpose, ambitions, values, and mindset. This mindset is exemplified by four behaviors: commitment, integrity, teamwork, and drive. Everything we do within the company is instilled with these behaviors.

Structured around a continuous improvement process, our management system allows us to continually improve on a systematic basis to ensure we deliver safe, efficient, and reliable products and services. Managers in our Continuous Performance Improvement organization facilitate deployment on both a geographic and product line level, and determine the best methods to lead people through the change process.

The pending Cameron acquisition is another aspect of the transformation’s focus on integration. In this case, integrating our reservoir and well technology with an industry leader in surface process and flow control will mark the start of a new epoch in drilling and production system performance. Customers will benefit from expanded technical capabilities, improved efficiency, and a closer commercial alignment to lower the cost per barrel and increase hydrocarbon recovery.

The transformation initially focused on improving performance in a market where rising E&P investment could not be met by range-bound commodity prices. The current low oil price market environment therefore makes our transformation goals even more compelling.

The Schlumberger transformation has contributed to consecutive years of financial outperformance that were undeterred when market conditions began to deteriorate in the second half of 2014. By focusing on resource management and exceeding our own standards for service quality, we are addressing the things under our own control. Transformation as a pathway to growth puts us in the ideal position when the market recovers and enables us to continue to manage the critical balance between margin performance and market share.

Where does our transformation story find us a few years down the road? At that time, the entire organization, its processes and systems, will have unified people and technology at an unprecedented level via integrated workflows. The result will continue to improve our customers’ business performance as well as our own.

In our quest to be one of the best-run companies in the world, we do not merely want to position ourselves ahead of the waves of change in the oil and gas industry. Schlumberger intends to be the oilfield services technology company that helps set those waves in motion.

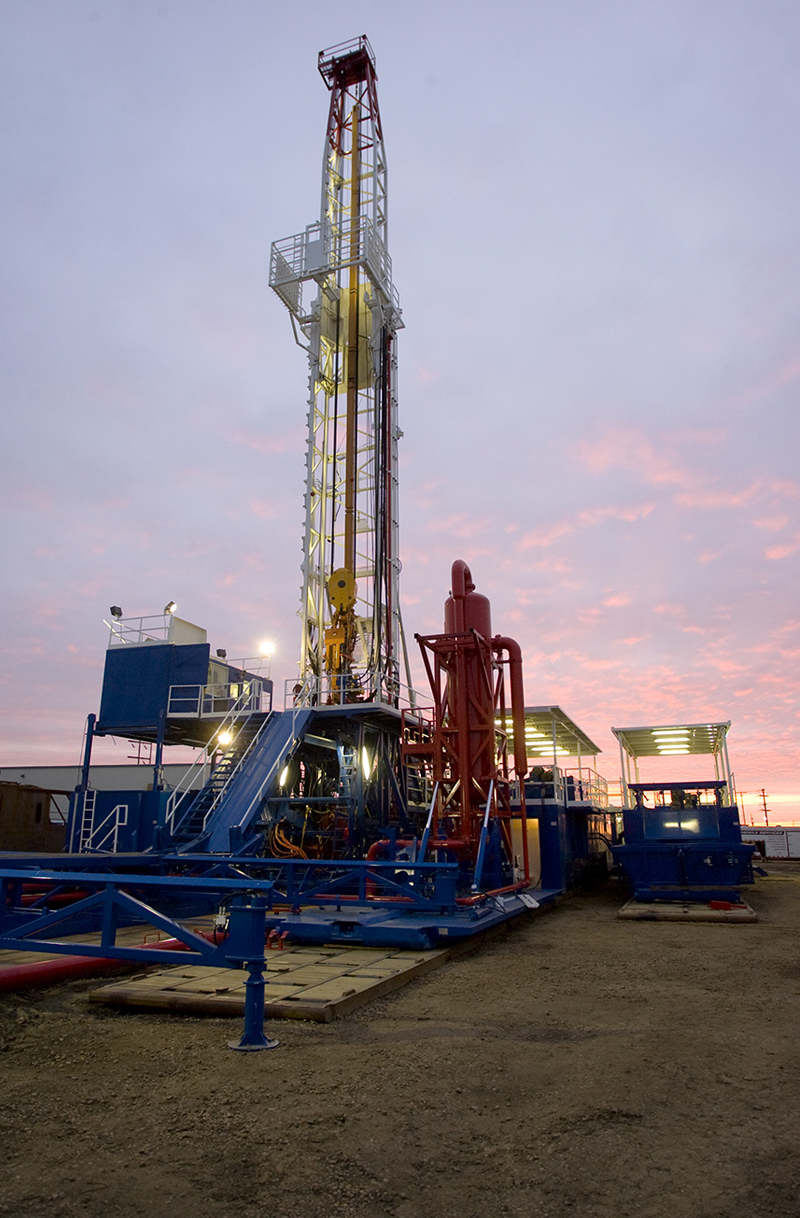

The Shushufindi-Aguarico field in Ecuador’s Oriente basin is the country’s largest oil field and produces approximately 16% of its oil. It is also an excellent example of the integrated oilfield services Schlumberger can provide.

The Oriente basin is part of a Mesozoic-Cenozoic back-arc basin that formed in conjunction with the tectonic activity that created the Andes Mountains during the Cretaceous to Tertiary Periods. Discovered in January 1969 with an estimated 3.7 billion bbl of original oil in place, the field produced its first oil in 1972. In 1986, field production peaked at 116,000 bbl/d. However, by 2010 it had decreased to approximately 43,000 bbl/d. Initially working with PetroEcuador and today with PetroAmazonas, Schlumberger and Tecpetrol formed the Consortium Shushufindi in 2012.

Early on, the consortium focused on reservoir studies to understand the field’s potential, conducted well interventions to increase production, and developed pilot programs to test production through water flood secondary recovery. An emphasis on integration and teamwork contributed to early success a year after the consortium formed, with four drilling rigs and seven workover rigs already in operation.

The commitment to integration has created operational efficiencies and the deployment of more than 50 specialized technologies. The Shushufindi-Aguarico field is currently producing 88,000 bbl/d, a rate not seen since 1995, and is becoming Ecuador’s highest producing asset. A strong emphasis on teamwork and integration contributed to today’s success.

Building upon the success in Shushufindi, Schlumberger went on to collaborate with PetroAmazonas through a long-term contract to increase production in Block 61. Discovered in 1970, the field has more than 360 wells that provide approximately 64,000 bbl/d or 12% of Ecuador’s total oil production.