How many ways can you add value to plate and pipe? We keep finding more.

IPSCO's success has always depended on finding new ways to add value to our products and services. We invested more than $50 million in a new plate heat treat facility in Mobile, Alabama to meet customer demand for increasingly advanced products. Heat treat capacity was similarly increased at our energy tubular facility in Calgary, Alberta and new tubular heat treat capacity is being installed at Blytheville, Arkansas and Baytown, Texas. We also continued to strengthen our leadership in large diameter pipe and are investing $80 million in our Regina, Saskatchewan spiral mills to increase annual capacity by 66% to 500,000 tons. In North America, IPSCO has more Grade X80 high-strength pipe in the ground than any other producer and is the first and only supplier of installed and operating Grade X100 pipe.

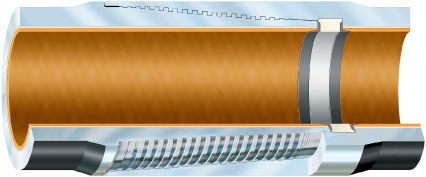

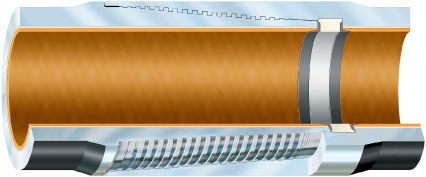

ULTRA-FXTM GL (Glass Lined)

ULTRATM Premium Oilfield Services manufactures and services the advanced connections required for deep, high-pressure and directional drilling.

|

|

|