Although data is at the center of E&P development, some exploration wells fall short of their objectives as a result of unexpected geology or unanticipated hazards. Increasing the volume and quality of accessible data equips the E&P industry to make better-informed decisions that reduce subsurface risk, optimize production, and maximize recovery—but only if that data is efficiently managed.

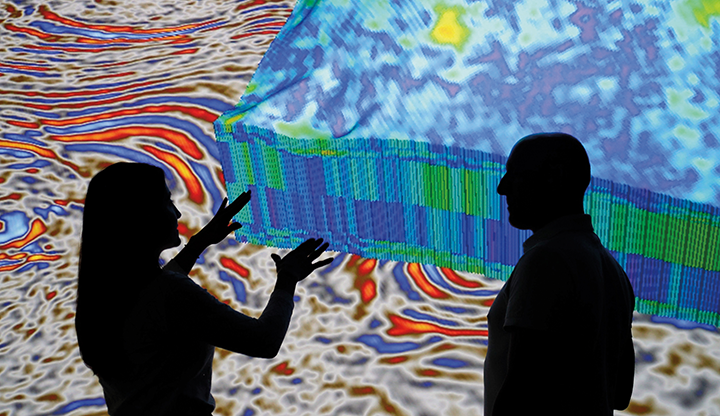

Petrotechnical experts working on exploration projects spend more than half of their time finding and preparing the data they need to make their decisions. The subsequent data interpretation is also very time consuming, and these interpretations drive important decisions for the reservoir’s development plan.

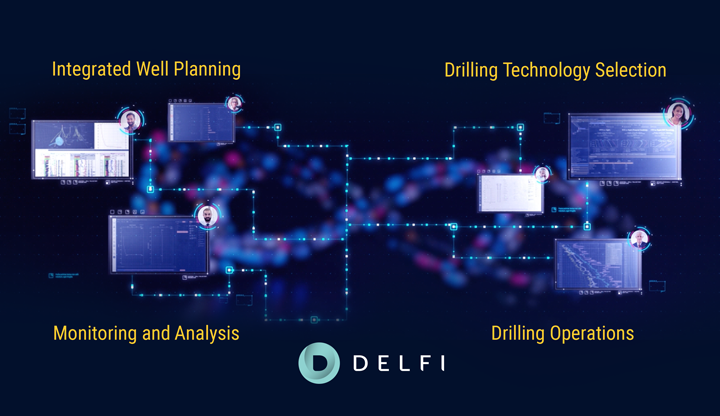

Changing the way the industry works begins with a critical assessment of how the data is used across reservoir characterization, well construction, and field production. During the development process as it is practiced today, different types of data exist in silos, making holistic analysis impossible. Without a system approach, precious information and time are lost because the lack of interface among different systems makes it difficult to share localized knowledge.

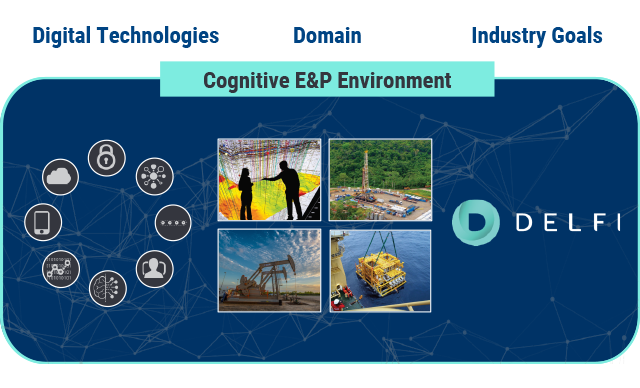

The DELFI cognitive E&P environment was developed to enable a new way of working. As the first of its kind in the oil and gas industry, this secure, cloud-based environment harnesses data, scientific knowledge, and domain expertise to fundamentally change the industry’s way of working. The new DELFI environment makes applications and workflows accessible to every user. Gone are the impenetrable silos, because in the DELFI environment, every stakeholder can build common workspaces for data, models, and interpretations while respecting proprietary information boundaries.

The DELFI environment provides the best possible representation of the surface and subsurface, including existing wells and facilities, plus those that are planned. The outcome is shared insight among all users and among all stakeholders to eliminate the silos of today. Performance is boosted as time cycles are compressed across the business, uncertainty in planning is reduced through greater understanding, and new opportunities are created to extend domain science into drilling and production operations. Everything working together enhances business value for both Schlumberger and its customers.

When Schlumberger launched the DELFI environment, the company deployed an E&P Data Lake on the Google Cloud Platform, which includes more than 1,000 3D seismic surveys, 5 million wells, 1 million well logs, and 400 million production records from around the world. This Data Lake makes data from different sources available through a common interface, making it easier for users to discover what the data is, have access to it, and use it to maximum advantage. As they work with this vast amount of information in the cloud, the result is a step change in scalability and performance.

The DELFI environment leverages data analytics, machine learning, high performance computing (HPC), and the Internet of things (IoT), all of which work together to maximize operational efficiency and deliver optimized production at the lowest cost per barrel. This environment facilitates a new level of integration among the geophysics, geology, reservoir engineering, drilling, and production domains. There are many workflows throughout exploration and production, and a digital approach accelerates access to all the available data. For that reason, the DELFI environment is also an open and extensible system in which Schlumberger customers and software partners can add their own intellectual property and workflows.

Schlumberger is an early adopter of HPC, and the teams at its technology centers—Menlo Park, California; Houston, Texas; Gatwick, UK; and Mumbai, India—have been leading the application of HPC for seismic processing. Today, Schlumberger has a state-of-the-art HPC infrastructure on the cloud that runs thousands of central processing unit (CPU) and graphics processing unit (GPU) nodes, and it is the largest cloud computer cluster of its kind in the oil and gas industry. Cloud-based HPC creates new opportunities for advanced visualization and machine learning to enhance the value of oil and gas data assets.

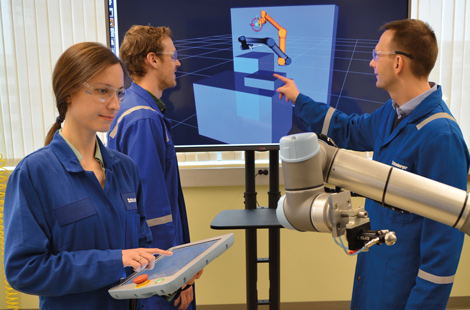

But how exactly does the DELFI environment change not just the way of working but also the nature of work? The answer is by enabling working in a common environment as well as creating accessibility and augmented intelligence for information sharing. Data is delivered to the right people at the right time so all recipients can maximize use of the latest information based on their role and expertise. Barriers to effective communication are eliminated, improving efficiency during the process so domain experts can spend more time on high-level solutions to the unique challenges every reservoir presents. Decisions that used to take days can now be completed in minutes.

The advancement of digital technology enablement within the oil and gas industry sets new demands in terms of cybersecurity. Schlumberger has been providing secure commercial software, information management, and IT infrastructure across the entire E&P life cycle for 35 years. In 2015, Schlumberger obtained Service Organization Controls 2 (SOC 2®) Type 1 and 2 accreditations for cybersecurity through an external audit. The SOC 2 accreditation provides detailed information about the controls Schlumberger has implemented in regard to security, availability, and integrity of the systems the company uses to process customer data as well as the confidentiality and privacy of the information that these systems process.

By working in the DELFI environment, oil and gas experts will be able to connect in a different way to complete shared work goals and expand their sphere of contact to other intellectually challenging domains. They will have access to tools and technologies that relieve them of routine, repetitive tasks, effectively freeing up their valuable time to focus on innovative solutions.

This new way of working is possible only by combining the latest offerings in digital technology with the domain know-how and hardware and software technology leadership that can optimize workflows, increase the efficiency of operations, and ultimately decrease the cost per barrel.