2004 Annual Report

|

2004 Annual Report |

|

|

Another productivity gain goes live. |

||

|

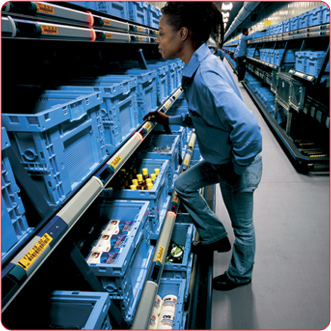

"A penny saved is a penny earned," wrote Ben Franklin. CVS has taken that credo to heart as we look for new and innovative ways to improve our cost structure. That, in turn, allows us to sell our products at attractive retail prices. Take our new, state-of-the-art distribution center in Ennis, Texas. The first facility of its kind in North America, it requires half the space of a conventional distribution center and needs one-third fewer people to run it. Yet, its storage and retrieval systems are capable of servicing the same volume and number of stores as a conventional facility twice its size. The Ennis facility even boosts in-store productivity because it selects and ships products customized to the layout of each destination store. That can significantly reduce the time it takes to get products from the delivery truck to store shelves. When our new Central Florida distribution center opens in late 2006, it will incorporate the same technology.

At the store level, the EPIC system has improved pharmacy workflow and cut costs, while our Assisted Inventory Management (AIM) system has taken the guesswork out of inventory tracking. AIM has helped improve our in-stock position and steadily increase our inventory productivity. Since 2001, we've used a combination of technologies to reduce shrink levels by more than 50 percent. For example, our VIPER software provides tools for analyzing front-store and pharmacy transactions. Sorting through 3 million transactions a day, it can quickly identify risk trends. We've brought VIPER and all our systems to the newly acquired Eckerd stores. With the acquired stores' initially higher shrink levels and cost structure, we see a significant opportunity for operating margin improvement. |

|

|

The first of its kind in North America, our highly efficient | ||

![]()

| © 2005 CVS CORPORATION::INVESTOR.CVS.COM |