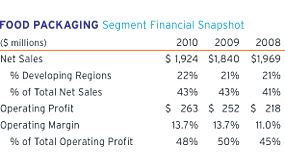

Food Packaging

2010 Key Product Launches/Expansions Include:

Oven Ease™ ovenable bags for bone-in or boneless meat, poultry and fish products combine barrier vacuum packaging with oven-ready convenience − allowing convenient cooking at up to 375°F/200°C, or re-heating within the package. The system reduces prep and cooking time, minimizes clean up and helps maximize flavor and product yield.

Oven Ease™ ovenable bags for bone-in or boneless meat, poultry and fish products combine barrier vacuum packaging with oven-ready convenience − allowing convenient cooking at up to 375°F/200°C, or re-heating within the package. The system reduces prep and cooking time, minimizes clean up and helps maximize flavor and product yield.

Cryovac Grip & Tear® bags, easy-open end-seal bags for fresh meats, poultry, and smoked and processed products, and cheese.

Cryovac Grip & Tear® bags, easy-open end-seal bags for fresh meats, poultry, and smoked and processed products, and cheese.

—Cryovac® Portion-Pull™ Bag, which provides multiple easy-open access points on larger-sized packaged cheeses typically found in deli-operations.

—Cryovac Grip & Tear® bags for frozen meat applications —Cryovac Grip & Tear® bags for post-packaging pasteurization of smoked and processed products.

—Cryovac® non-barrier Grip & Tear® bag for whole fresh poultry.

Multi-Seal® package, an easy open and reclosable deli package that is currently piloting in non-meat applications as we expand usage in areas such as snack foods.

Multi-Seal® package, an easy open and reclosable deli package that is currently piloting in non-meat applications as we expand usage in areas such as snack foods.

Freshness Plus® oxygen scavenging systems and odor scavenging materials.

Freshness Plus® oxygen scavenging systems and odor scavenging materials.

PakFormance® integrated packaging solutions, including PakFormance® Remote Diagnostics and our "Ready-to-Pack to Ready-to-ShipSM" philosophy combine hardware, software, equipment and services that give food processors control and oversight of the food packaging process from start to finish.

2010 Awards include:

- 2 Dupont Awards for Packaging Innovation

- Ameristar Gold Award

- Flexible Packaging Association Highest Achievement & Gold Awards

- Food Processing's Readers Choice &mdash Gold Award