Components, techniques, and workflows that can

be propagated to different technologies to match dif-

ferent environments are necessary for the wide

range of today’s E&P. Slim, horizontal wells in uncon-

ventional reservoirs require the same measurements

and quality as deep, offshore conventional wells but

the hardware must be capable of navigating tight

doglegs or working at higher limits of temperature

or pressure. The unique through-the-bit approach of

ThruBit* logging service exemplifies this, providing

a complete measurement suite for shale gas devel-

opment from a small-diameter toolstring. With a

diameter of only 2

⅛

in, the logging toolstring is

sufficiently slim to pass through the center of most

drillpipe, jars, and drill collars and out the opening

of the specifically designed Portal* drill bit.

Integration of ThruBit service—a company acquired

by Schlumberger in 2011—with Schlumberger meas-

urements continues with the addition of borehole

sonic services for geomechanical evaluation to the

ThruBit service platform.

Integrating Drilling Technologies

Once the well location has been selected on the

basis of high-quality characterization and a shared-

earth model, drilling performance becomes fundamen-

tal to cost-effective well construction. Improving the

industry’s typically suboptimal workflows begins with

establishing three objectives. The first is to increase

overall drilling efficiency, which is a function of the

rate of penetration and the time actually spent drilling.

The second is to precisely place the well and acquire

formation evaluation data to maximize production

and further reservoir characterization. The third is to

provide wellbore assurance throughout the well’s

productive life.

Optimizing the drilling workflow for these three

objectives is a complex and multidimensional challenge.

It begins with a commitment to research and engineer-

ing, which must be approached in an integrated multi-

disciplinary manner because the technical solutions

span a spectrum of scientific disciplines. Optimization

also demands access to all the components of the

9

Nothing fully replaces visual examination and laboratory

measurement of rock samples recovered from a

reservoir. Schlumberger XL-Rock* large-volume rotary

sidewall coring service, which cuts sidewall cores with

a rock volume equivalent to that of conventional core

plugs, matches the industry’s standard sample size to

limit the expense of conducting conventional continuous

coring. Integration of downhole measurements and

samples to calibrate the digital with the physical

confirms understanding of the reservoir and the

interaction between rock and fluid.

Traditional core analysis data are central to a variety of

activities and span the life cycle of a field. Measurements

are integrated into the evaluation of reservoir geology,

reservoir engineering, and, later in the life of a field,

enhanced oil recovery. Rock property data are integrated in

seismic studies, log interpretation, reservoir simulation

modeling, and stimulation and completions decisions.

Schlumberger has provided laboratory analysis of reservoir

fluids for more than 40 years, and following the acquisition

of TerraTek* rock mechanics and core analysis services

in 2006, digital rock and fluid analysis services are now

integrated across a global network of reservoir laboratories.

The latest offering, CoreFlow* digital core and fluid analytics

services, integrates rock and fluid laboratory work

with digital core scanning and digital fluids to

improve the quality of information for reservoir

analysis and for input to reservoir models.

Integration with Physical Measurements

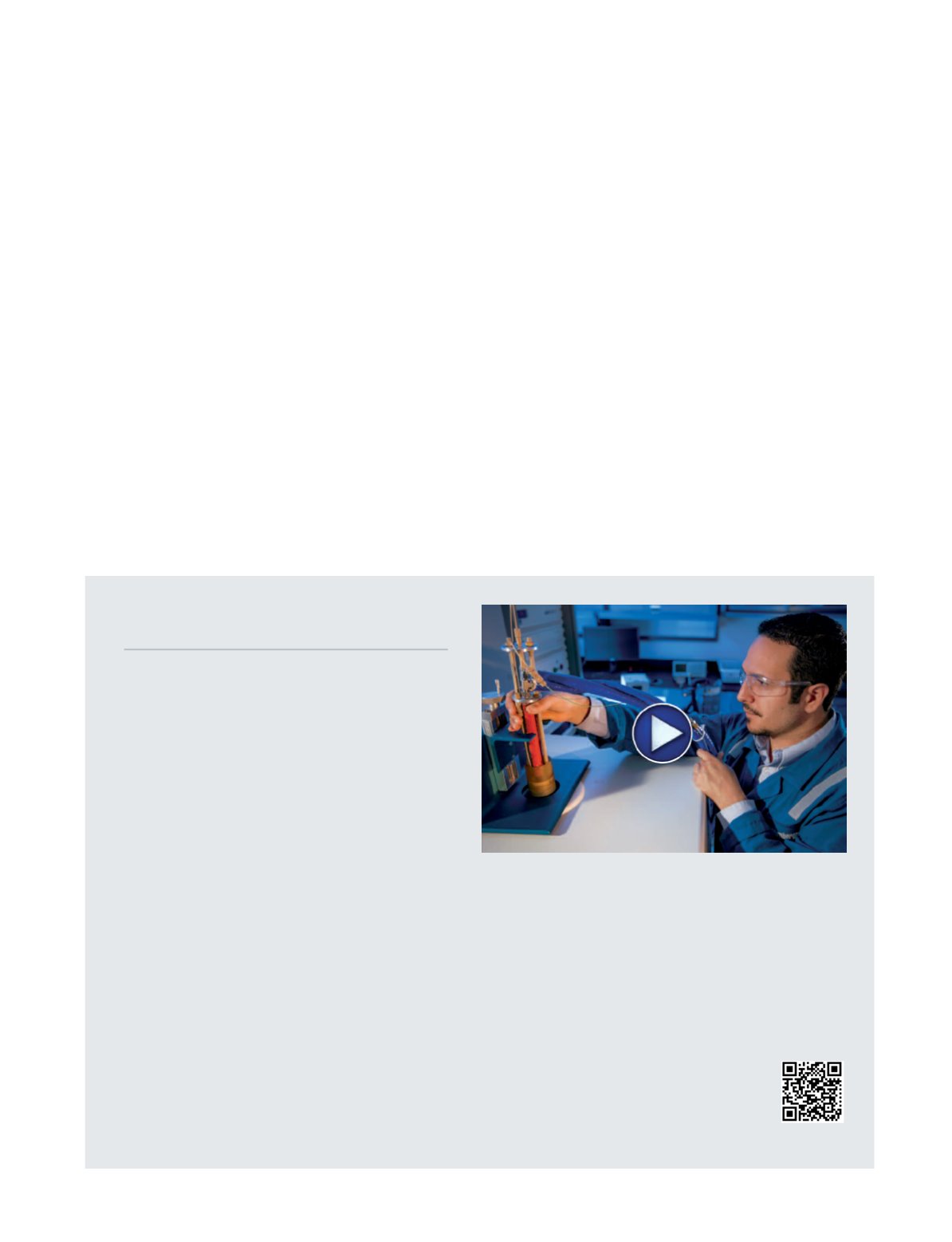

NMR Laboratory Specialist Kenneth Bohn at the Schlumberger

Reservoir Laboratory in Houston loads a core sample into a

nuclear magnetic resonance device.