completely upgrading our methodology and practices

toward significantly increasing return on investment.

Five years later, we have largely completed the trans-

formation of the organization by creating a unified

global structure in which engineering, manufacturing,

and field support teams work together closely,

spanning REMS centers and technology product lines.

This structure, modeled from the best practices of

leading engineering and manufacturing companies,

covers all aspects of our product development efforts,

including design methodologies, test and qualification

principles, manufacturing techniques, and the capture

and use of data from field operations. We employ prac-

tices that combine the LEAN and Six Sigma principles

that have driven reliability and performance improve-

ments in other high-technology industries, such as auto-

motive and aerospace. The Schlumberger product

development system focuses on advancing performance

in three principal directions: shortening product devel-

opment time, improving product reliability, and reduc-

ing the total cost of ownership for all of our products.

One way of achieving performance gains is a plat-

form engineering approach that enables running the

same measurement sensors on different methods of

conveyance and combining complementary measure-

ments on the same platform. This yields economies of

scale through standardized components that are com-

mon to a number of different tools. For example, the

fundamental Wireline hydraulic tool platform powers

different formation tester configurations as well as

the XL-Rock large-volume sidewall coring service. This

concept has led to the creation of the Enabling

Technology Group (ETG), which is charged with find-

ing and developing new oilfield technologies together

with establishing common technical building blocks

that optimize efficiency and reduce technical risk

during the product development process.

To function as efficiently and effectively as possible

in providing its expert services to all Schlumberger

product development teams, the ETG aligns its aims

not only with product group plans for new technology

but also with the ideas that emanate from the research

organization. With this perspective, ETG can identify

common opportunities to assess which are most likely

to have the greatest impact. This in turn drives

14

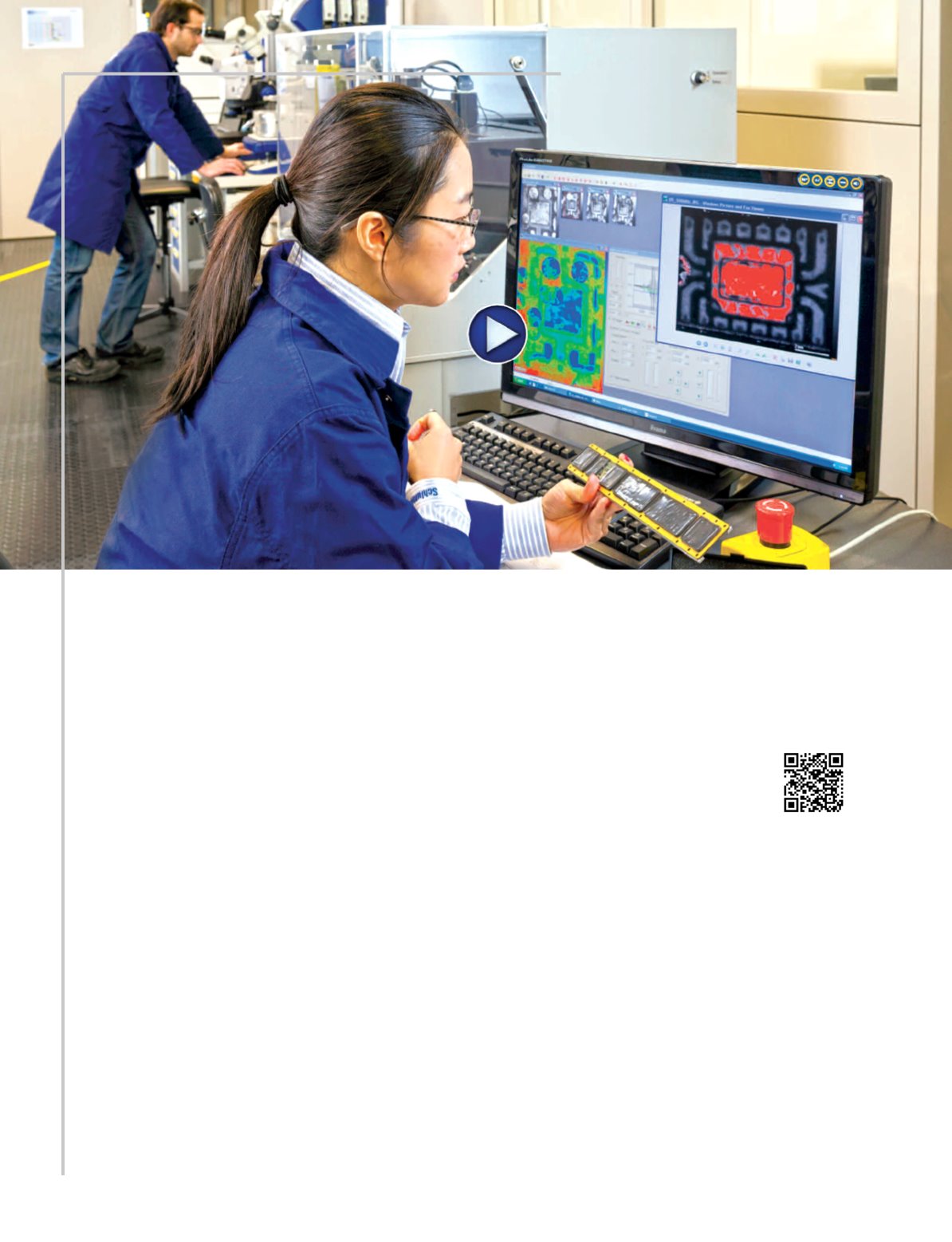

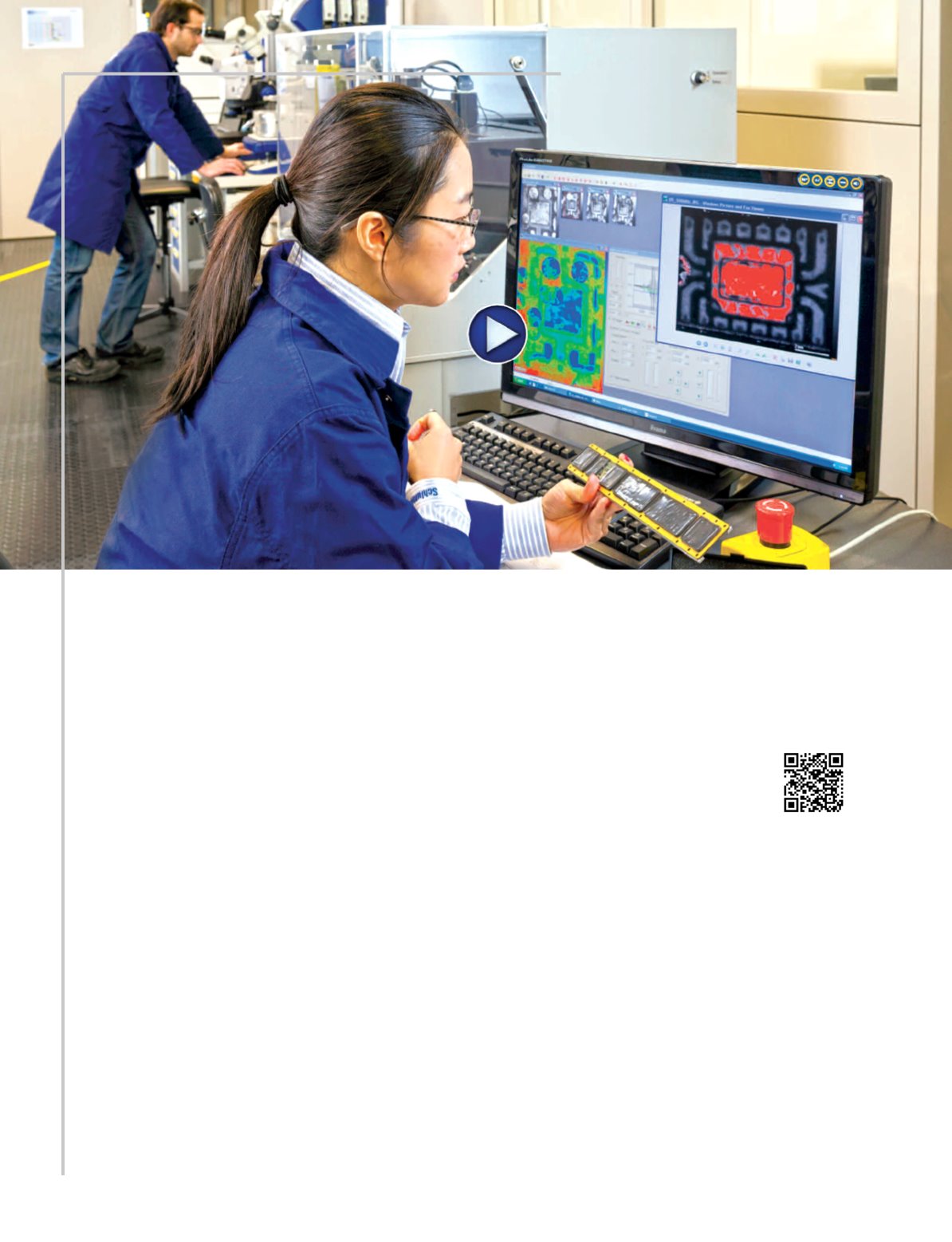

Downhole equipment is subject to high temperatures and

pressures as well as mechanical shock. Electrical Technology

Engineer Suriyakan Vongtragool Kleitz examines a circuit

board in Clamart, France, with an acoustic microscope

to identify potential weaknesses following a series of

qualification tests.