15

technology sourcing, the identification of potential

partners, and eventually the validation and verifica-

tion processes.

One of the greatest challenges faced by research

and engineering is the extreme conditions that oilfield

technologies work under. Downhole equipment is sub-

ject to high temperatures and pressures, violent

shocks, and corrosive environments. It is these envi-

ronmental conditions that differentiate oilfield tech-

nology mission profiles from those of other industries

with similar data and measurement requirements.

While this challenge is nothing new, the complexity of

future hydrocarbon resources is continually growing

the environmental envelope deeper, hotter, and longer.

As a result, technology components must be exten-

sively tested to validate and verify their performance.

ETG takes the lead in this activity with specialized test

equipment and laboratories within the network of

Schlumberger engineering and manufacturing centers.

Technology standardization also brings advantages

to the field organization. In fact, harmony among the

product lines reinforces the Schlumberger operating

model introduced with the organization of GeoMarket

regions in 1998. That model promoted integration

between technology deployment and field operation by

housing operational crews from different product lines

under the same roof. The advantages were clear—

shared services provided common support, while prod-

uct line integration enabled more efficient delivery of

oilfield services through mutual proximity—from

single service to integrated project management. The

geographical GeoMarket regions also improved effi-

ciency through regional knowledge, customer contact,

and relevant technology deployment.

Today’s combination of the integrated Schlumberger

REMS organization with the GeoMarket region struc-

ture directed by product group coordination is laying

the foundation for even higher levels of service qual-

ity. One important enabler is a new generation of

fit-for-purpose operations bases providing fully inte-

grated levels of service delivery. These bases achieve

complete integration of all active product lines in a

given area while consolidating resources and logistics

and optimizing operational processes and mainte-

nance layouts. In the last two years, nine such bases

have been opened in as many countries, representing

an investment that exceeds $350 million while deliv-

ering incalculable value to operators.

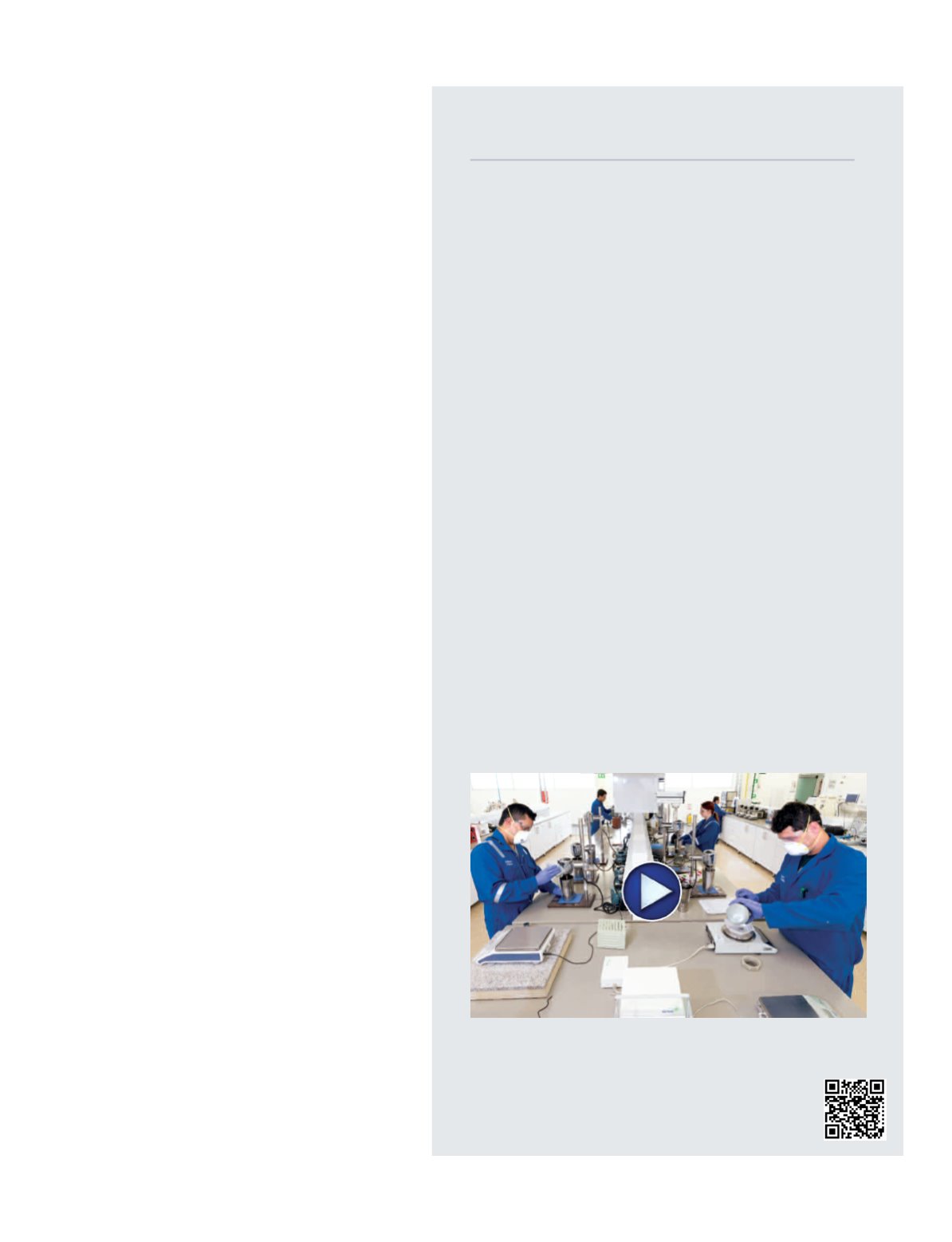

The Cota integrated facility in Bogota, Colombia—one of several

such bases inaugurated in 2013—was designed to facilitate synergy

between Schlumberger product lines to improve integration,

efficiency, quality, and safety.

The facility, which covers 122,000 m

2

, combines the latest

Schlumberger technologies, experienced personnel, and advanced

workflows in logistics, materials management, maintenance

planning, operations monitoring, and resource management.

Integration leads to increased efficiency. For example, engineered

well construction services are supported by state-of-the-art

laboratories and modeling software, enabling field engineers and

petrotechnical experts to reduce prejob cycle time. To expedite the

maintenance of tools and field equipment, each product line has

dedicated workflows to guide tools into the maintenance area and

through predetermined steps prior to final quality control checks.

The process is supervised by maintenance experts in close

collaboration with the field engineers and technicians who use

these tools in the field.

Tools and equipment to be sent to the field undergo a final test in

the integrated test bay. All major tool functions, including safety

features, are tested under the supervision of qualified experts, and

the test logs are analyzed before final release. All records are

archived for traceability and can be accessed both locally by field

engineers and technicians and remotely by engineering center

support staff overseeing a larger fleet of assets.

Integrated Operations Bases

Integration of laboratory testing with field operations leads to

increased efficiency and reduced risk. Laboratory technicians

in the Cota integrated facility test drilling fluid rheology and

density before use in the field.