Our goal was to develop a more agile structure to respond to market conditions and simplify the interface between field operations and support functions.

In the beginning, we identified approximately 14,000 people in the company who performed tasks that would be under the purview of the SSO. Once identified, we categorized the tasks into functional areas in order to streamline the organizational structure and centralize certain tasks within geographical or regional locations. Once we built the SSO platform, the next step was to develop best-in-class functions and explore how to further optimize their processes.

The next phase is to move from a function-based approach to a process-based approach, which enables the product lines to be more customer focused.

The shared services concept is not new, of course, as other best-in-class companies have successfully applied it to individual functions within their businesses (e.g., HR, finance, IT). Schlumberger, however, applied the shared services concept to bring together seven functions under one roof: finance, HR support, IT operations, procurement and sourcing, contracts, distribution, and facilities and construction. This effectively eliminated the siloed approach associated with tasks that were duplicated across multiple product lines.

Collectively, the SSO model benefits from three distinct business principles. By sharing volume-sensitive services across product lines, we create economies of scale and eliminate superfluous efforts. Transferring best practices across businesses and leveraging expertise and know-how capture economies of scope. Lastly, tailoring the level of service to meet a product line’s needs achieves scalability. The service categories we identified can be performed at a higher level of quality and improved cost levels under the SSO than if they are pursued individually by each product line.

As the SSO reduces its operating costs, this can reduce the costs for individual product lines as well. For example, implementing a new logistics framework optimized the $1.2 billion the product lines collectively spent on these services. This created numerous benefits, such as faster turnaround for tools and improved project readiness for deepwater operations.

The Manggar facility in Balikpapan, Indonesia, is an excellent example of how optimizing field operations support creates synergies and cost savings within product and service delivery workflows. Before 2014, the nine product lines in this facility worked independently to complete 28 common tasks that were divided between 21 field direct employees, 28 base personnel, and 16 third-party contractors.

In addition, a 20% increase in field activity unsettled the work-life balance of field direct employees in the Well Services, Well Intervention, Completions, and M-I SWACO product lines. Analysis identified the amount of time personnel spent on each task and its relative complexity. After grouping tasks into several categories based on similarities in the scope of work, they were mapped to the personnel best suited to complete the work. For example, a few tasks were assigned to the Materials group while others were consolidated and managed by one product line for all of them. However, the majority of tasks were assigned to a Shared Base Support organization made up of three teams: operations, maintenance, and administration. The overarching goal was to consolidate existing facility personnel and avoid the need to increase support services headcount.

Optimizing Manggar base support in September 2014 meant that 21 field direct employees can now solely focus on field operations and avoid spending time on common tasks at the base. This also helped field personnel regain their work-life balance while simultaneously accommodating the current increase in field activity. The Manggar Shared Base Support transformation story created a capacity gain of 16 base personnel, which avoids the need to increase headcount, and also amounts to an annualized cost savings of approximately $1 million while maintaining a high level of service quality.

Now that we have defined functions under the SSO, the next phase is to move from a function-based approach to a process-based approach, which enables the product lines to be more customer focused. This would identify one person as the focal point, with ownership of every stage of the process and charged with continually seeking to optimize it.

Furthermore, as the company continues to grow its business through organic and inorganic means, the SSO will take advantage of business synergies and ensure that it offers superior levels of service at the lowest transactional costs.

For example, the Cameron acquisition, which is still subject to regulatory approvals, will integrate our reservoir and well technology with an industry leader in surface process and flow control and marks the start of a new epoch in drilling and production system performance. Cameron has five product lines—drilling systems, subsea, surface systems, valves and measurement, and process systems—and thus there is very little product line overlap with Schlumberger. Customers will benefit from expanded technical capabilities, improved efficiency, and a closer commercial alignment to lower the cost per barrel and increase recovery.

The Schlumberger global footprint includes 500,000 transactions a month and a global inventory currently with a value close to $5 billion. Optimizing the SSO will have a substantial impact on our financial performance. When our footprint increases to include Cameron, we will be able to expand upon the benefits of our transformation due to our increased buying power and cost synergies.

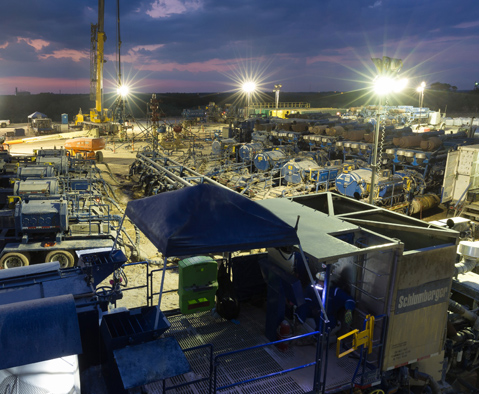

Well Services hydraulic fracturing operations in North America land have seen multiple benefits from adopting new ways of working to optimize the supply chain function. The procurement and timely delivery of high-quality proppant and fluids to the wellsite are critical to the success of hydraulic fracturing operations.

Recognizing that the supply chain can be a differentiator in the dynamic North American hydraulic fracturing market, Schlumberger has taken it to a new level by more closely aligning the supply chain with business needs through Sales & Operations Planning (S&OP). This included creating a consistent process for S&OP, introducing professionalized planning systems, and improving the connectivity between the supply chain and the business.

In addition, Well Services centralized the management of product allocation and delivery. Here the main emphasis is on managing proppant via the creation of a product control tower that focuses on minimizing landed costs to the operating locations. This centralized hub does all of the planning, tactical sourcing, and purchase order generation to ensure cost-effective, industry-leading service delivery of proppant to the field. In 2015, control tower personnel oversaw the delivery of 5.2 million tons of proppant to the wellsite, equivalent to the weight of approximately 712 Eiffel Towers.

Logistics plays an important role in product allocation and delivery. A centralized logistics tower oversees the movement of product and equipment used in North American hydraulic fracturing operations. State-of-the-art IT, including mobile technology, enables efficient carrier procurement and invoicing and provides real-time visibility of our logistics network. In 2015, Well Services made nearly 300,000 trips to the wellsite to deliver proppant, fluids, and equipment over a distance of 52 million miles—equivalent to nearly 2,100 trips around the equator.