| Wall Modules and MACT Testing

for Hanford Waste Treatment Plant |

|

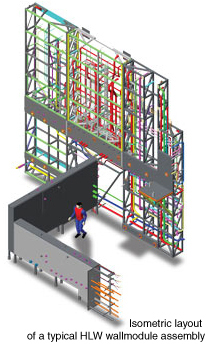

Over recent months, Duratek scientists and engineers assigned to the DOE Hanford River Protection Project’s Waste Treatment Plant (RPP-WTP) effort have been completing various work packages for Bechtel National, Inc. In April 2005, Duratek completed the design of various wall modules for the RPP-WTP High Level Waste (HLW) vitrification facility. These modules allow service utility, control hook up, and monitoring lines to safely penetrate the thick, concrete shield walls of the WTP facility for remote operation of the vitrification process. Once fabricated, these panel-like modules will be incorporated into the walls of the HLW vitrification facility, and in turn, will be filled with concrete to provide radiation shielding to the operations staff. Each module can contain a dozen or more penetrations of the shielded wall, designed to provide safe, shield access for a specific service line. In March 2005, Duratek’s long-term research partner, the Vitreous State Laboratory of The Catholic University of America, completed a series of pilot-scale melter testing to provide regulatory permitting data for the RPP-WTP vitrification process. These Maximum Achievable Control Technology (MACT) tests involved the efforts of dozens of scientists, engineers, technicians, operators, and regulatory personnel to assure the data collected met the needs of the RPP-WTP facility. With the completion of the MACT tests, Duratek’s pilot melter test program (HLW and LAW), successfully completed their missions for Bechtel National. From 1999 to 2005, more than eight million pounds of test glass were produced in the two pilot melter systems. This program collected a variety of large-scale operational data for use by designers, operators, and regulators. |

|