|

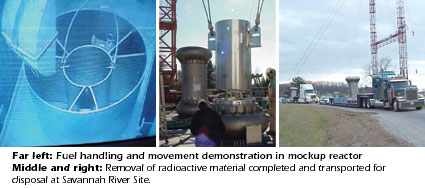

In December 2003, Duratek successfully

completed, under budget and on schedule, de-fueling of the Tower

Shielding Reactor (TSR-II) located at the Tower Shielding Facility

(TSF) at the U.S. Department of Energy’s (DOE) Oak Ridge National

Laboratory (ORNL). The TSF was built in 1953 as part of the

Aircraft Nuclear Propulsion Project under the Atoms for Peace

program.

In October 1992, the DOE ordered the facility to be placed

in a standby mode and scheduled de-fueling, radioactive materials

removal, and building demolition for 2009. All safeguards

commensurate with nuclear security and reactor safety had

to be maintained throughout this period. With the events of

September 11, 2001 and the resultant need for increased security,

DOE included TSF and TSR-II on its list of facilities targeted

for accelerated closure. In the first quarter of 2003, DOE

Assistant Secretary for Environmental Management Jessie Roberson

directed that the reactor be de-fueled, the fuel dispositioned

to the DOE Savannah River Site, and any radioactive source

materials removed in preparation for controlled demolition.

With these actions taken, the facility could be downgraded

to a “radiological” facility, yielding an estimated $1.95

million in savings between 2004 and its original fuel removal

date of 2009.

Duratek brought in experienced and specially trained personnel

from Master-Lee Energy Products (MLEP), with known capabilities

in the commercial nuclear industry for refueling and radiological

decontamination. A full-scale mockup of the reactor was constructed

from original design drawings, hand-drawn 25 years ago, in

the ORNL archives. Thirty percent of the fuel assemblies were

fabricated to demonstrate safe fuel handling and movement

techniques.

During the initial characterization and radiological surveys,

Duratek discovered that sludge and debris had accumulated

in the bottom of the reactor pool, and analysis indicated

elevated levels of PCB and lead contamination. Further investigation

showed that the concrete pool floors, walls, and steel support

structures were painted with a surface coating known as zinc

chromate paint that was developed in the early 1960s and contained

various components that were not regulated at that time, such

as chromium, lead, and PCBs. The pool was coated with a liner

developed by MLEP (InstaCote®) to make the pool viable through

the full duration of mockup training and reactor de-fueling

activities. Before application of the liner, the existing

coating was stripped using a 40,000-psi hydro-blaster.

Duratek designed an innovative dewatering system to extract

the PCB and lead contaminants, leaving solids in the dewatering

box. Additional carbon filtration was used to perform the

final contaminant stripping from the water. The filtered water

was tested and met the Waste Acceptance Criteria for PCB and

lead. These liquids were trucked to the Duratek-operated ORNL

Liquid Waste Processing System for further processing.

PCB and lead contaminants, along with the power of the hydro-blast

equipment, required the use of waterproof or resilient personal

protective equipment (PPE) and full-face supplied air. Heat

indexes between 85º and 100ºF were frequently encountered,

which mandated constant monitoring of vital signs of all personnel

for heat stress. Work durations were limited to 15 minutes

in ambient temperatures between 85º and 95ºF, followed by

monitoring of vital signs, core body temperature logging,

and a minimum one-hour rest and fluids rehydration period.

Severe ambient temperatures above 95ºF resulted in the reduction

or suspension of heavy work activities until conditions improved.

By successfully completing this important project for DOE,

Duratek reduced the radioactive facility “footprint” at the

Laboratory, resulting in a net savings of about $2 million

in maintenance and security costs. The facility has been placed

in a safe shutdown condition awaiting ultimate demolition

of the buildings and towers in 2009.

Said Bob Sleeman of DOE’s Oak Ridge Operations Office (ORO),

“These cost savings will be used for other high-priority projects

in our accelerated cleanup of the Oak Ridge Reservation.”

Added John Gadd, Project Manager for ORO prime contractor

Bechtel Jacobs Company, “[The Duratek project team] made this

project the benchmark for safe, successful project execution

[and] contributed to its success by taking ownership for tasks

and performing them safely and professionally. The project

epitomized [the DOE Integrated Safety Management System] in

action with [Duratek’s] input to the work, before and after

execution.”

|