> Rubicon’s vertically integrated manufacturing capabilities provide a unique and valuable level of control and self-reliance.

> We touch every part of the sapphire value chain—from designing and building our own furnaces through delivery of finished products.

> Our ability to maintain quality and volume while increasing crystal size is a result of our end-to-end process and years of experience.

Vertical

Integration

Rubicon’s end-to-end manufacturing capability, coupled with strong intellectual property, results in an advantageous cost structure and provides for better control of product quality and delivery schedules.

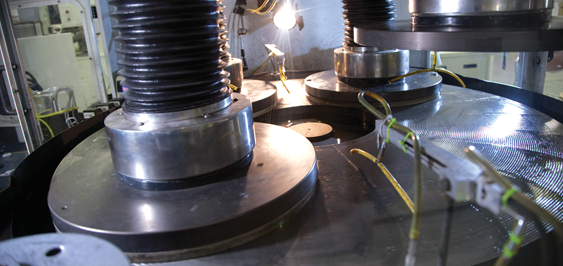

Rubicon’s vertically-integrated, state-of-the-art manufacturing facilities leverage our internally developed raw material processing capability, proven and proprietary ES2 crystal growth technology, high-precision core drilling, wafer slicing, surface lapping, large-diameter polishing and wafer cleaning processes to set the industry benchmark. This end-to-end manufacturing capability, coupled with strong intellectual property, results in an advantageous cost structure and provides for better control of product quality and delivery schedules.

For Rubicon, vertical integration begins with raw material. During 2011, we developed the in-house capability to purify and densify raw powdered aluminum oxide into the type of material used to initiate the crystal growth process. This capability gives Rubicon more control over supply and quality and, when fully implemented, will result in significant cost savings.

At the heart of our proprietary technology is sapphire crystal growth. Rubicon has been designing and building its own crystal growth furnaces for over ten years and employs many of the world’s leading material scientists and sapphire production engineers. This knowledge has resulted in sapphire crystals of exceptional purity and quality and has enabled a continued evolution in the size of the crystals produced. Growing larger sapphire crystals while maintaining superior quality is a very complex process. In addition, fabricating these crystals into larger-diameter wafers with the exacting specifications dictated by our customers requires sophisticated equipment and extensive process engineering. Far from “off the shelf” capabilities, they are developed and refined over time…and with experience.

Rubicon’s experience in all of the processes involved in manufacturing sapphire products has resulted in cost efficiencies throughout the system and has enabled us to provide industry-leading levels of quality and service. Cost and quality leadership are fundamental to the acceleration of LED adoption in the marketplace—and are strategic priorities for Rubicon.

Looking to the future, we continue to invest in Research and Development to extend our leadership position and introduce new products to help our customers gain greater efficiencies. Wherever you see a leading-edge sapphire substrate technology innovation, Rubicon will be there.