The Plan is Clear and Comprehensive

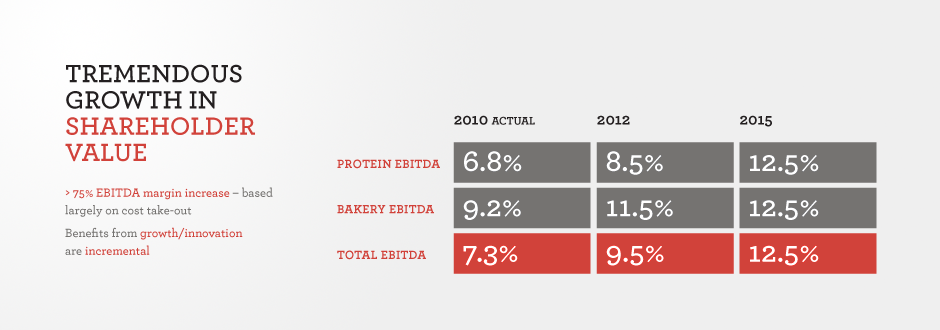

We will drive profitability and increase our long-term competitiveness and lower our cost structure by reducing the complexity of our supply chains and by investing in scale and technology.

Scale and technology investments were neither necessary nor affordable when the Canadian dollar was at $0.65 compared to the U.S. dollar. Today, they are achievable and mandatory. This requires fully integrating our current manufacturing base of over 85 plants, and consolidating production at fewer, larger, dedicated plants.

Scale is essential to competing and winning in the North American food industry. We are seeing the advantages flowing to our North American competitors that have made this investment. Through our analysis and planning, we know precisely what scale will mean for Maple Leaf – a 15% to 25% reduction in manufacturing costs and a 60% improvement in productivity. Aggregating our category volumes into large, single, high-technology sites using the latest in materials handling, robotics and packaging will create real and lasting change in the profitability and competitiveness of our business.

While the magnitude of the task is significant, the scope of initiatives is not new to the Maple Leaf management team. We have a deep and successful track record of executing complex initiatives, including those of similar size and nature as planned in our five-year blueprint. Of course, we are also mindful of risks – mostly centred on the demands of completing this work all concurrently and in relatively short time frames. This is where our well-seasoned execution disciplines will pay dividends.

We are making excellent progress – ahead of schedule and under budget – on the construction of our new “mega-scale” bakery in southern Ontario. Once completed in mid-2011, it will be the largest and most efficient bakery of its kind in North America. This new bakery will reduce overhead costs, increase productivity and advance our capacity to support new product innovation.

The benefit of these capital investments will be further enhanced by the work already underway to simplify our product lines and reduce complexity. In our prepared meats business, we have launched a major initiative to substantially reduce the over 4,000 different types of prepared meat products in our system,

We are making excellent progress – ahead of schedule and under budget – on the construction of our new “mega-scale” bakery in southern Ontario.

Once completed in mid-2011, it will be the largest and most efficient bakery of its kind in North America.

a legacy of our numerous acquisitions and a regional supply chain network. In many cases the differences are minor – a slight difference in product size or packaging specifications. In some cases there will be a reduction in overlapping regional brands. We began to realize early benefits from this work late in 2010 and simplification across other major categories will continue through 2011. Making fewer, higher volume products is also a prerequisite to ensuring we gain cost efficiencies from scale plants.