| NEXT |

|

|

|

|

|

During 2000, ICPG continued its growth and expansion to better serve customers in both the industrial and consumer product markets. Early in the year, work began on an upgraded tube and core production facility at our Taylors, SC site. This new plant began production at year-end and is one of the largest and most modern operations serving the synthetic fiber and yarn markets in the U.S. Further growth for the year in the industrial packaging market came from establishing new remote warehouse locations for the Protect-A-Board edge protector product line. We now have six customer-focused warehouses located in Chicago, IL; Columbus, OH; Denver, CO; Kernersville, NC; Memphis TN and Phoenix, AZ. Production increased at the New Smyrna Beach, FL plastics plant by 40 percent as a result of implementing a 7-day, 24-hour work schedule. Work was begun near the end of the year on doubling the capacity of this operation to meet increasing customer demand for printed plastic caulk tubes. This new capacity is expected to be fully operational by the end of first quarter 2001.

|

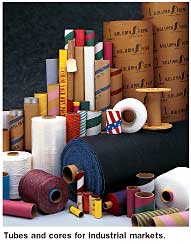

Significant research and development provide new and improved products to meet important customer needs, such as the development of new surface finishes for high-grade film applications and enhanced yarn carrier configurations for improved productivity at customer operations. Caraustar continues to be the leading producer of carpet cores in the U.S. Early in the 1970s, Caraustar introduced a convolute-wound core known as Konva-Kore at the Dalton, GA plant, which is still considered the product of choice for winding carpet in the growing carpet industry in north Georgia. Today, the ICPG includes 43 operations, made up of 31 tube and core locations, 3 composite container locations, 2 injection molded plastic product operations, 5 Protect-A-Board manufacturing sites, one adhesive operation and one transportation facility. As the second largest manufacturer of tubes, cores and composite containers in North America, plans for the future include new market penetration through the development of new products and maintaining low-cost manufacturing centers to ensure the future success of Caraustar and our customers.

|

|

13 |

|

| NEXT |

|

The

acquisition of Arrow Paper Products in Saginaw, MI was completed

in the fourth quarter of 2000 and was consistent with the strategy

of geographical expansion to better service multi-plant customers.

Equally important, this acquisition provided a number of new product

lines to Caraustar — including tubes for window shades, tubes

for winding consumer rolls of film and products for unique automotive

applications.

The

acquisition of Arrow Paper Products in Saginaw, MI was completed

in the fourth quarter of 2000 and was consistent with the strategy

of geographical expansion to better service multi-plant customers.

Equally important, this acquisition provided a number of new product

lines to Caraustar — including tubes for window shades, tubes

for winding consumer rolls of film and products for unique automotive

applications.  In

the third quarter of 2000, work began on a new composite can plant

located in Stevens Point, WI. This plant is being equipped with

some of the latest technology for composite can manufacturing and

will produce packaging for powdered beverages, snack foods and other

food products. Start-up of this facility is scheduled for early

in 2001.

In

the third quarter of 2000, work began on a new composite can plant

located in Stevens Point, WI. This plant is being equipped with

some of the latest technology for composite can manufacturing and

will produce packaging for powdered beverages, snack foods and other

food products. Start-up of this facility is scheduled for early

in 2001.