|

LETTER TO OUR SHAREHOLDERS Cliffs Today

Given the business outlook, the recent bankruptcies

of Wheeling-Pittsburgh and LTV and the weak financial

position of other partners and customers, Cliffs has

significant challenges ahead. The LTV bankruptcy filing resulted in a relatively

modest charge to fourth quarter results. However,

there are substantial contractual obligations and

management relationships between Cliffs and LTV, and

non-performance by LTV could have a significant impact

on Cliffs and/or the Empire Mine. The closure of LTV's

wholly-owned mine in Minnesota on January 5th is expected

to make LTV a major iron ore customer of Cliffs in

2001 and beyond, under a multi-year sales contract

executed in 2000. LTV is also a 25 percent partner

in the Empire Mine. Since its filing, LTV has continued to meet its obligations as a partner of Empire, and we expect LTV will purchase its iron ore pellet requirements from Cliffs. However, LTV has neither affirmed nor rejected its ownership in Empire or its ore purchase contract with Cliffs. In addition, there is much uncertainty relating to the level at which LTV's steelmaking facilities will operate. Bill Calfee, Cliffs' executive vice president-commercial, is chairman of the LTV Unsecured Creditors Committee, and we are committed to achieving a satisfactory outcome. The steel and iron ore business in North

America is going through a painful process

of restructuring whereby only the strongest

facilities are likely to survive. This

will ultimately produce a stronger, more

competitive industry, but the path in

the near term is fraught with difficulty

and uncertainty. We are managing our iron

ore business with the expectation that

integrated steel and iron ore production

capacity will continue to shrink, and

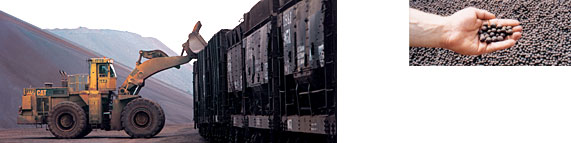

foreign competition will remain intense. We believe Cliffs can be a stronger factor in a consolidating

North American pellet market. Most of our pellet capacity

is competitive, on both a cost and quality basis,

but all of our mines can improve their position. While

we have always

We recognize that we must do more and are challenging all areas of our organization to ensure that we are being as cost efficient as possible:

While our business plans are not dependent on reducing imports of steel and iron ore, Cliffs and its steel company partners and customers need a level playing field to deal with foreign trade. Unfairly dumped foreign steel imports are systematically eliminating North American steel capacity, and unfairly imported steel slabs are cutting into the iron ore market. U.S. steel imports, including steel slabs, totaled 38.0 million tons in 2000, the second highest amount in history. There is significant excess steelmaking capacity in the world, and the United States is a magnet for the surplus due to our weak enforcement of existing trade laws and a strong dollar. Foreign steel companies are selling steel in the United States at prices that are below what it costs to produce, and that is a violation of U.S. trade laws. We are hopeful that the Bush Administration and the 107th Congress will work together, on an urgent basis, to address our country's steel emergency. This is also a vital issue in Canada, and the Canadian government has a steel anti-dumping investigation in progress following complaints by steel producers in Canada. |

|||||

focused on cost and quality, we need to make dramatic

changes in the way we operate to serve a "new"

steel industry. Our objective is to be the most admired

minerals company, and we are not going to let any

barriers to improvement get in our way.

focused on cost and quality, we need to make dramatic

changes in the way we operate to serve a "new"

steel industry. Our objective is to be the most admired

minerals company, and we are not going to let any

barriers to improvement get in our way.