Among the primary discoveries were the need to balance technical ambitions with commercial ones and to take better advantage of the size of our company. In particular, this applied to our broad technical community and the use of proven building blocks that we describe as enabling technologies.

Investment in new technology development is something that Schlumberger has always highly valued.

One outcome was the formation of the Enabling Technologies Group, a new part of the product development organization. The group creates and develops technical building blocks that help reduce the technical risk on major product development programs. These are created simultaneously with product development with the ambition to have a set of standardized components that can be used in multiple products. This approach is more cost effective and helps improve our ability to commercialize on time.

Furthermore, our out-of-the-box product delivery is now more reliable than it was due to an approach that includes improved project management, aligning enabling technologies, and engaging concurrent teams early in the process. The transformation not only allowed us to refine the development and commercialization process, but also accelerated it to get more new products to the market.

As a technology company in the global oil and gas services industry, we knew our sheer size would create its own set of challenges as we set out to transform the way we work. Investment in new technology development is something that Schlumberger has always highly valued, even in downturns, and it enables us to emerge from difficult times with a stronger portfolio to assist our customers in achieving their objectives.

Among the first technologies to benefit from the transformation of our product development process was the TeleScope ICE* ultrahigh-temperature measurements-while-drilling service. The technology is a milestone in an extensive line of Schlumberger measurement-while-drilling services, which were first introduced in the 1980s as a means to optimize well trajectory in real time.

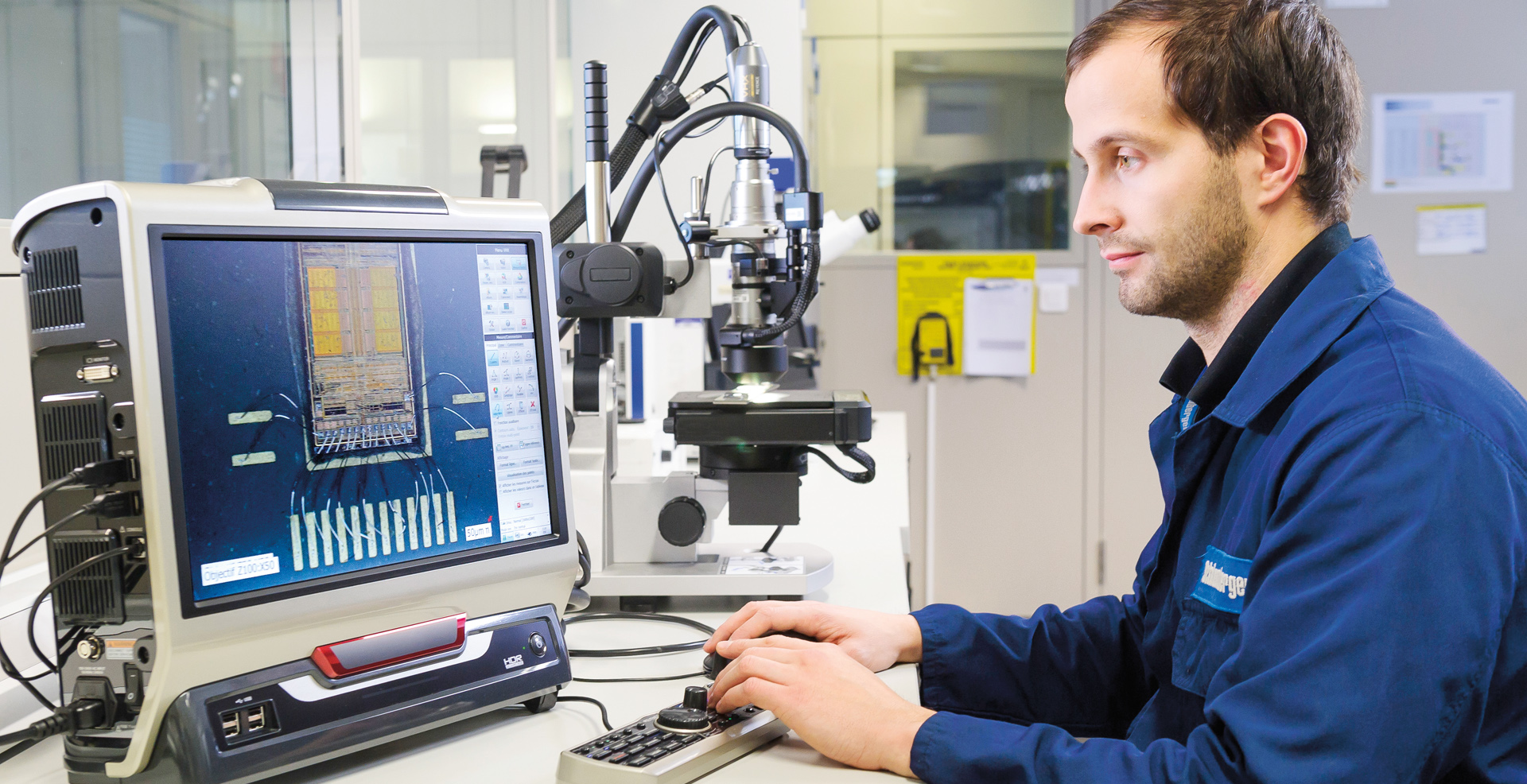

TeleScope ICE service uses proprietary microelectronics that are ruggedized to withstand the challenging conditions associated with drilling ultrahigh-temperature reservoirs. Schlumberger engineers applied a systems engineering approach borrowed from the aircraft industry. The design process included defining potential failure modes and finding solutions that were expected to have the highest impact on reliability.

Key priorities included an improvement in product reliability along with the reuse of some of TeleScope ICE service’s technical components, or enabling technologies, in the design of other tools and services. Accordingly, TeleScope ICE service was tested beyond the limits of its mission profile to build in additional reliability.

The proprietary microelectronics in TeleScope ICE service are also used in PowerDrive ICE* ultrahigh-temperature rotary steerable system and Signature* quartz gauges. The technology employed by PowerDrive ICE service means that customers can now use a rotary steerable system in ultrahigh-temperature reservoirs.

Examples such as these, in which enabling technologies are used across multiple product lines, are the direct result of the transformation of our product development process. This avoids a siloed approach to product development and also provides economies of scale as the manufacturing costs for these technical components decrease.

After assessing how to increase reliability, efficiency, and integration, we concluded that there were certain disciplines we needed to add or reinforce in our product development teams. Thus, we complemented core engineering skills with skills from manufacturing engineers, supply chain specialists, and reliability and maintainability experts, sometimes with experience from other industries.

In manufacturing, we started our focus on the application of LEAN principles on the production line. Today, a Schlumberger manufacturing facility looks very different than it did 10 years ago. Standard Work Instructions (SWI), visual workflows, and improving the required skill levels for various manufacturing operations now dominate. Our assembly and manufacturing lines are thus more agile and efficient, achieving greater levels of quality and more unit output per line.

A litmus test of any commercialized product is the level of reliability it achieves during its early introduction. In the past it was not uncommon for us to create a task force to resolve problems that arose after new releases. However, products developed using our new method have demonstrated significant improvements and we no longer have to create task forces. Overall, the product development transformation created a 60% increase in our ability to introduce new and higher-impact technologies per dollar spent.

Today, the more than 80 centers that make up our Research and Engineering, Manufacturing, and Sustaining organizations use the Schlumberger Product Development Method, the proprietary result of a $350 million investment to transform the way we develop technology. The technologies resulting from this investment exhibit increased quality and reliability and achieve higher levels of efficiency compared with previous generations.

What does product development look like for Schlumberger in the future? With the size and breadth of our organization, our teams will build systems that are integrated at the design stage in order to improve product reliability and efficiency in our customers’ workflows.

Software and data are key drivers to achieving these goals and are what we refer to as IT enablement. Combining this with the way we manage our hardware development portfolio makes product development more efficient. By capturing the important data at the front end, we are better equipped to make data-driven decisions that help to perfect design during the development process. Similarly, IT enablement makes the manufacturing systems of the future more agile and efficient, particularly when customizing a product for a specific application.

Furthermore, by focusing on industrialization at the front end of the design process, we can respond to customer input more swiftly when it comes to the customization layer around a product platform’s core design. This approach also makes us more adaptable in meeting customer requirements in a timely manner as the oil and gas market rapidly evolves.

Though the initial phase of the engineering and manufacturing transformation is complete, we continue to evolve, especially the manufacturing process. Future goals include the extensive use of automation, in particular for large-volume products, and building digitally enhanced factories that provide continuous information that helps us achieve greater levels of quality, efficiency, and cost reduction.