|

|

| S A F E , S E C

U R E R A D I O A C T I V E M A T E R I A L S D

I S P O S I T I O N |

| www.duratekinc.com |

Bear Creek Eliminates Aged

Waste

by Assef Azadeh |

By

1999, Duratek had in place contracts to process the radioactive

waste generated from the decommissioning of three nuclear power

plants. To present an idea of how much waste that is, a decommissioning

plant generates around 50 times more waste in weight than an

operating plant. A large part of this increase comes from the

dismantlement of the buildings and includes materials like concrete,

metal, and large components. A great deal more waste was coming

in than was being shipped out, and this waste began to accumulate

on site. By

1999, Duratek had in place contracts to process the radioactive

waste generated from the decommissioning of three nuclear power

plants. To present an idea of how much waste that is, a decommissioning

plant generates around 50 times more waste in weight than an

operating plant. A large part of this increase comes from the

dismantlement of the buildings and includes materials like concrete,

metal, and large components. A great deal more waste was coming

in than was being shipped out, and this waste began to accumulate

on site.

The problem with the large quantities of waste was compounded

by the fact that the processing services were competitively

and aggressively bid, leaving little room for delays and error.

In fact, the Commercial Processing group contributed to significant

losses to Duratek as a corporation both in years 2000 and 2001,

primarily because of the issues associated with aged waste.

(Aged waste is material that has not been processed within 365

days.) Starting in 2001, Duratek was left with approximately

two million pounds of aged waste: a huge challenge, and a significant

concern for both customers and our shareholders.

Beyond implementing new waste processing strategies, Duratek

took comprehensive and aggressive corrective actions, including

organization and management changes, new accounting and tracking

systems, and other cost reductions. An empowered and motivated

team faced its aged waste challenge. Throughout 2002, Duratek

reduced the aged waste inventory and achieved ZERO aged waste

at the end March 2003, where it has since remained.

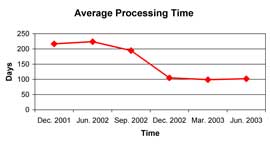

In accordance with the continuous improvement philosophy and

to enhance excellence in customer care, Duratek is proud to

report that with the elimination of aged waste it has substantially

improved the average waste processing times, reducing cycle

time by approximately 50 percent since 2001. The approximate

100-day cycle time provides Duratek with optimum resource leveling,

allowing time to schedule, plan, and campaign specialty waste

streams along with the routine waste processing. In addition,

this cycle time reduction (1) reduces costs for storage, containers,

tracking, surveys, etc.; (2) allows more accurate invoicing;

and (3) addresses customer concerns regarding liabilities associated

with unprocessed waste and the potential for double payment.

Duratek is proud of the fact that the Commercial Processing

Group recovered and delivered on commitments to its customers

at no additional cost. With the improved controls in place,

Duratek is now cost-effectively processing more waste, with

less people, in less time. Duratek is here for long-term industry

needs helping to cost-effectively mitigate the risk of dispositioning

radioactive materials. |

|

|