DOE Hanford Site Cleanup Progress Well Decommissioning Project Completed Final Disposition of 183-H Basin Waste

The last of more than 12,000 drums of mixed low-level waste were shipped from Hanford’s Central Waste Complex (CWC) to the Duratek-operated Environmental Restoration Disposal Facility (ERDF) for treatment and disposal—marking the end of surveillance and operations costs associated with long-term storage and making room for TRU waste being prepared for disposal at the Waste Isolation Pilot Plant in Carlsbad, New Mexico. Finding a suitable pathway to disposal was a challenge for the 183-H waste stream since it was managed under a different regulatory agency (the Resource Conservation and Recovery Act, or RCRA) than ERDF, which is managed under the Comprehensive Response Compensation and Liability Act of 1980 (CERCLA). A CERCLA determination removed the waste from RCRA management and allowed it to be managed under CERCLA. Rhonda Connolly, Waste Services Director and Duratek employee, said, “We were able to reach our goal because we had cooperation among the regulators and contractors, and because of the dedication of our employees.” The MLLW Treatment and Disposal Project developed a shipping process that met all Department of Transportation requirements, and was efficient enough to allow for multiple daily shipments. “It was an enormous task to establish the path forward for shipping this waste to ERDF,” said Jodi Durfee, project lead and shipper. “We had to introduce ourselves to CERCLA requirements and find a way to make the process as efficient as possible while still meeting all of the regulations and requirements.” With the shipping process in place, a dedicated crew on shift, and leased equipment on hand, the first of more than 300 shipments made the four-mile trek from CWC to ERDF in July 2003. “It is an amazing thing when a plan comes together,” Durfee said. “This project was projected to take three years and we completed it in less than two.” Disposal of the 183-H Basin Waste not only helps other site projects by freeing up storage space at CWC, but ultimately, and most importantly, it moves us one giant step closer to completing the Hanford Site’s cleanup mission. (top) Milestone for Retrieving Transuranic Waste Met Five Months Early

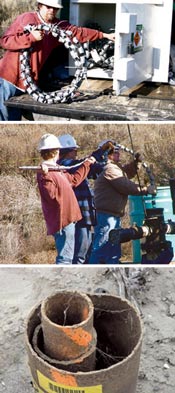

Duratek has assisted in the retrieval of more than 13,500 drums containing transuranic (TRU) waste, beating a Tri-Party Agreement milestone by five months. Workers met last year’s annual milestone for retrieving the equivalent of 6,000 drums four months early. “Your accomplishment in meeting another important TPA milestone ahead of schedule is outstanding,” said Ron Gallagher, Fluor Hanford President and CEO, in a message to employees. He commended the project for safety performance (zero OSHA-recordable injuries since retrieval operations began in 2003). Duratek has assisted in the retrieval of more than 13,500 drums containing transuranic (TRU) waste, beating a Tri-Party Agreement milestone by five months. Workers met last year’s annual milestone for retrieving the equivalent of 6,000 drums four months early. “Your accomplishment in meeting another important TPA milestone ahead of schedule is outstanding,” said Ron Gallagher, Fluor Hanford President and CEO, in a message to employees. He commended the project for safety performance (zero OSHA-recordable injuries since retrieval operations began in 2003). The containers contain low-level radioactive waste, mixed low-level waste (also containing chemical contamination), and TRU waste in the form of contaminated debris, tools, clothing, and other materials. The containers were stacked on asphalt pads, covered with plywood, draped with tarps, and then covered with dirt. To ensure worker safety, crews follow a methodical process for retrieving the drums. As the drums are pulled one-by-one from the stack, each is visually inspected for corrosion, dents, or bulges, and storage records are reviewed to determine the kind of waste in each container. “Our employees have had to handle more and more degraded containers as they’ve progressed in retrieving material that has been in the trenches longer,” said Dale McKenney, Fluor Hanford V.P. of Waste Stabilization and Disposition and Duratek employee. Added Doug Greenwell, Director of the TRU Retrieval Project and Duratek employee, “As a result, they’ve developed several new techniques for moving these corroded drums without causing further damage.” Keith Klein, DOE’s Richland Operations Office Manager, said, “This is a critical risk-reduction milestone met well ahead of schedule. Pulling these containers out of the trenches eliminates the threat they pose to the surrounding environment and allows us to make an increasing number of shipments of transuranic waste out of Washington State for disposal.” |

Fall 2005

(past issues)

single-casing wells would not be able to perforate the multiple casings of the Webster Wells (named for the person who had them installed in the 1970s and 1980s).

single-casing wells would not be able to perforate the multiple casings of the Webster Wells (named for the person who had them installed in the 1970s and 1980s). The Hanford Site’s Waste Stabilization and Disposition Project (WSD) met a crucial milestone requiring that 240 cubic meters of mixed low-level waste (MLLW) be thermally treated by September 30, 2005. This milestone—part of a Tri-Party Agreement (TPA) between the DOE, the U.S. Environmental Protection Agency (EPA) and the State of Washington—satisfied requirements set in The Resource Conservation and Recovery Act (RCRA), which gives the EPA authority control over waste management activities. Specifically, it provides for the management of hazardous wastes from the point of origin to the point of final disposal

(i.e., “cradle to grave”).

The Hanford Site’s Waste Stabilization and Disposition Project (WSD) met a crucial milestone requiring that 240 cubic meters of mixed low-level waste (MLLW) be thermally treated by September 30, 2005. This milestone—part of a Tri-Party Agreement (TPA) between the DOE, the U.S. Environmental Protection Agency (EPA) and the State of Washington—satisfied requirements set in The Resource Conservation and Recovery Act (RCRA), which gives the EPA authority control over waste management activities. Specifically, it provides for the management of hazardous wastes from the point of origin to the point of final disposal

(i.e., “cradle to grave”).