6

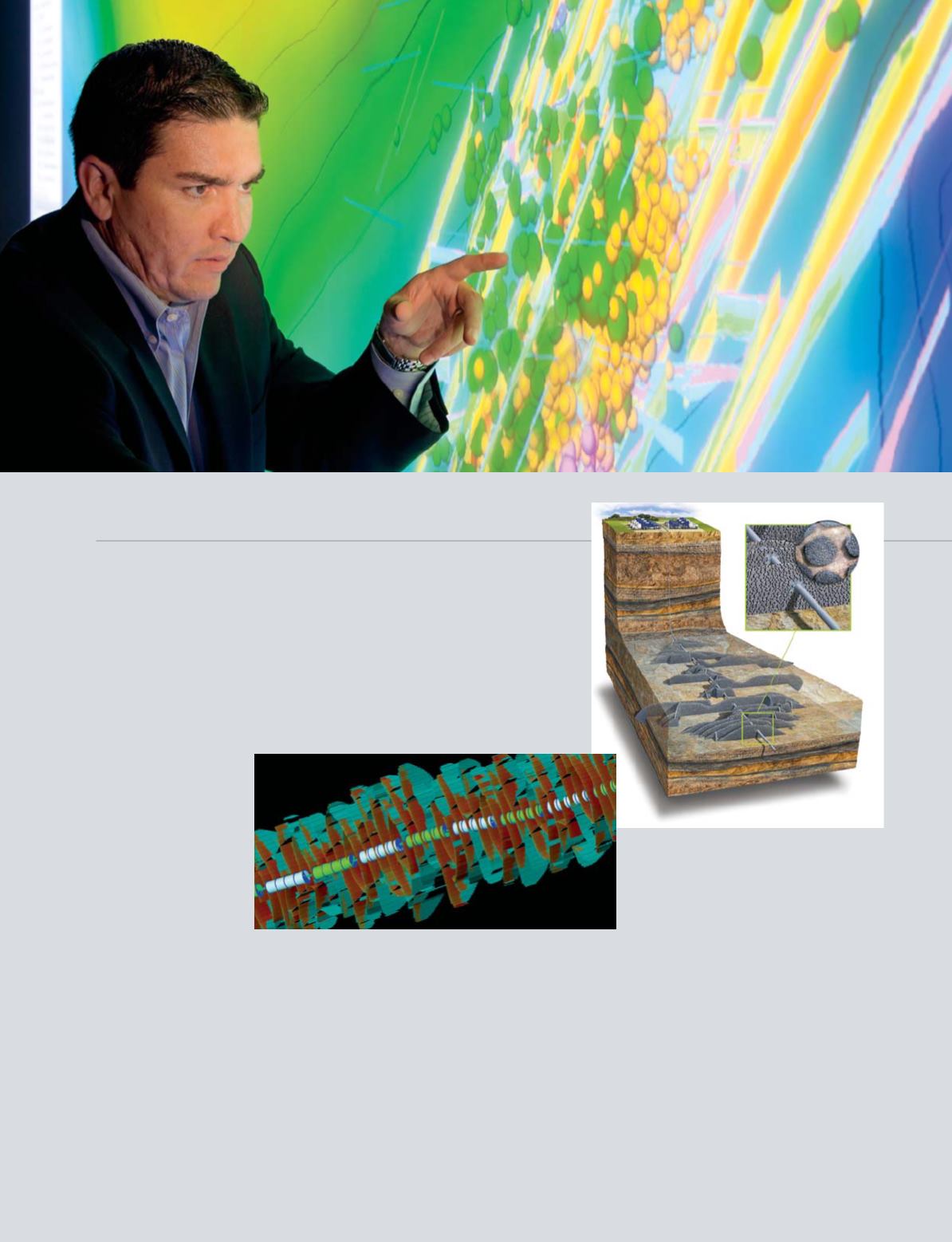

Top, Salvador Ayala, Schlumberger Well

Production Services vice president of

marketing and technology, studies

mapped fracture paths generated by

StimMAP* hydraulic fracture stimulation

diagnostics. Knowledge of the physical

dimensions of the fracture network

ensures effective and efficient opera-

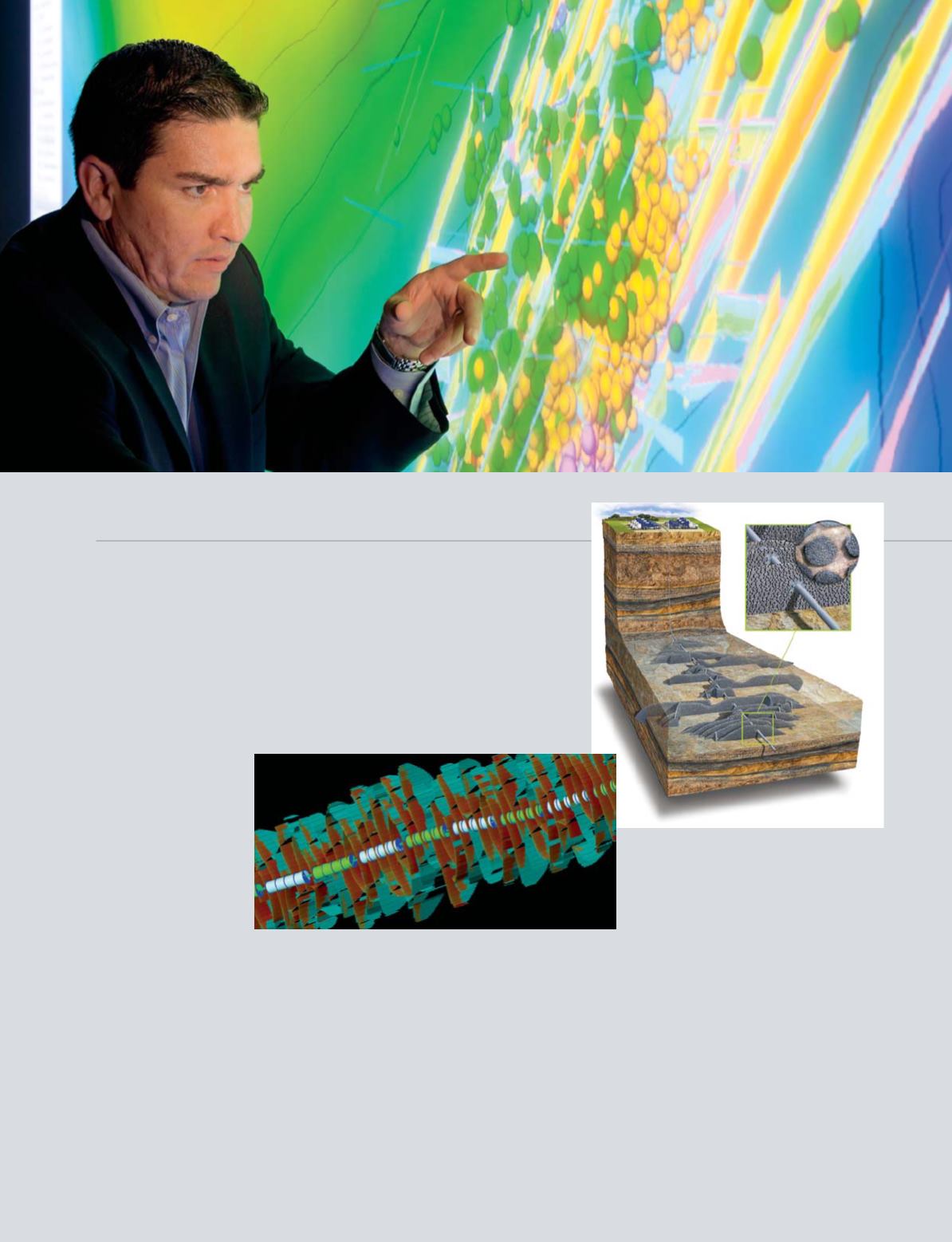

tions. The lower-left figure shows

Mangrove workflow results that identify

the best intervals to complete—

in green—in a horizontal well and the

center diagram demonstrates how

HiWAY technology forms channels in

the fracture network.

One of the keys to successful fracture stimulation is first placing the wellbore in the most

favorable part of the reservoir, where the highest porosity and best permeability exist,

and then focusing the hydraulic fracturing operation on that same part. Although new

technologies such as the HiWAY* flow-channel hydraulic fracturing technique can achieve

considerable savings over conventional techniques, it is clear that the fracturing effort

cannot succeed without knowing where to put the fracture. Fracturing technology has

developed extremely rapidly in oilfield terms—only a decade ago, hydraulic fracturing

still employed a brute force approach to attempt stimulation of long sections of a well

that typically crossed reservoir zones of limited potential. What was lacking were the

necessary modeling and

interpretation techniques

for unconventional

reservoir evaluation and

development.

By applying science,

Schlumberger has

developed an integrated

reservoir modeling

workflow that harnesses

the power of HiWAY

technology to multistage completion equipment that directs the proppant to the most

favorable reservoir zones and monitors the development of the fracture network by

“listening” to the rocks as they open. The workflow, using Mangrove* software running

on the Petrel* E&P workflow platform, also integrates technologies from the

Schlumberger Production Group with Reservoir Characterization Group surface and

downhole seismic measurements, core analysis, and standard wireline logging and

logging-while-drilling data. The result is a three-dimensional reservoir model capable

of predicting the variations of unconventional reservoir quality for determining the best

well locations and the best reservoir zones.

Unconventional Reservoir Workflow