Deep Ultraviolet

Our DUV light sources include the most advanced ArF immersion light sources for use

on the most critical process layers. Chipmakers also use our ArF and KrF light sources

to fill out or balance their production lines or add capacity to their manufacturing

facilities (also referred to as “fabs”) for less critical layers.

The extremely short wavelengths and highly narrowed bandwidths of our light sources

work in concert with our lithography customers’ steppers and scanners and their

sophisticated lens systems to help enable the very fine feature resolution required

for patterning today’s most advanced semiconductor circuitry. In addition, the pulse

energy and repetition rate of our light sources enable our chipmaker customers to

achieve high throughput in wafer processing. We have designed our light sources to be

reliable, easy to install and compatible with existing semiconductor manufacturing

processes. Additionally, we offer focus drilling technology for certain of our ArF

immersion light sources. Focus drilling provides up to two times improvement in the

depth of focus on the wafer, which can positively impact chipmakers’ yield.

In addition to our current DUV product portfolio of light sources, we have numerous models of ArF and KrF light sources that have been superseded and are no longer in active production. However, these systems are still widely used by our customers and make up a substantial portion of our installed base of light sources. We continue to provide installed base products and maintain parts inventory for these systems.

XLR Series

XLR Series

XLR Series—193 nm ArF Immersion Light Sources

As chipmakers continue to reduce the feature sizes and shrink CDs on the wafer, they

need to install the advanced tools required to enable patterning of the most critical

layers. NAND flash memory and DRAM semiconductor manufacturers have been the most

aggressive chipmakers in shrinking CDs, and have been driving demand for our most

advanced light sources for ArF immersion lithography applications. DRAM manufacturers

are in production with CDs at 45 nm. Currently, some chipmakers are in development of

chip production with CDs of less than 32 nm. Leading edge semiconductor manufacturers

in the memory, logic and foundry sectors have been developing ArF immersion extension

down to CDs of 22 nm and implementing double-patterning technique, which means the

increased demand for ArF immersion light sources could last for several years. The

XLR Series is based on our dual discharge chamber master oscillator power amplifier

(“MOPA”) light source architecture, with a regenerative ring amplifier in place of the

traditional power amplifier. Built on our XL universal platform, this product series

offers a step function improvement in performance and cost of operation. Our XLR light

sources are designed to enable our chipmaker customers to customize performance for

specific applications through improved performance parameters and metrology options.

Flexible power up to 90 watts (“W”), improved bandwidth stability and dose control

enable higher CD control and yield, and this series offers longer pulse duration to

extend the lifetime of the illuminator and lens, even at higher power levels. Cost of

operation is reduced significantly through optical design and component robustness,

leading to increased module lifetime. With active bandwidth stabilization and tuning

capability, the XLR light sources offer improved bandwidth management for improved

mask optical proximity correction matching and tool-to-tool matching, so customers can

use multiple node mask sets in the same tool or the same mask in different tools. We

sell primarily the XLR 600ix model of this series.

XLA Series

XLA Series

XLA Series—193 nm ArF Dry Light Sources

Though no longer considered leading edge technology, dry ArF lithography is still used

to pattern a significant number of less-critical layers on wafers. Additionally, as CDs

continue to shrink and drive demand for even finer resolution on the most critical

layers, non-critical layers may be patterned with ArF dry scanners, which drives

continued demand for these tools. Our XLA Series of ArF light sources was the

first product series to be based on our dual-discharge chamber MOPA architecture.

MOPA represented a paradigm shift in excimer laser architecture when it was introduced

in 2003. The master oscillator creates a narrow bandwidth beam of light at low power.

The beam then is directed into the power amplifier, where the power is increased

significantly while maintaining the narrow bandwidth. This combination of bandwidth

and power enabled our chipmaker customers to continue reducing CDs and increasing

processing speeds, capacity and functionality of chips, while giving them the

performance and cost advantages they need. Each product in the XLA Series is based

on the XL universal platform, and we continue to sell the XLA 105 model of this series.

ELS 7010

ELS 7010

ELS 7010—248 nm KrF Dry Light Sources

We have been providing KrF light sources for volume chip production since 1996,

when chipmakers required the adoption of DUV light sources in their fabs. Over the

years, we have developed and sold a variety of increasingly powerful and productive

KrF light sources. The 7000 Series is the first series that was designed and built

on a common platform, enabling chipmakers to easily utilize the 193 nm wavelength

produced by ArF and the 248 nm wavelength produced by KrF within the manufacturing

environment. This “ease of use” feature was very important at the time because

chipmakers were introducing ArF production into their fabs and the common platform

simplified the introduction of this new technology. With a 4 kHz repetition rate and

high output power, the 7000 Series provides our chipmaker customers with high wafer

throughput and lower cost of operation by reason of advanced design and materials,

and delivers a high level of tool availability to enable manufacturing efficiency and

flexibility. Our bestselling light source of the series, the ELS-7010 is still in

demand as chipmakers continue to prefer the higher power and narrower bandwidth offered

by this system. In 2010, we introduced the ELS-7010x which allows customers to easily

adjust power from 30 watts to 50 watts based on the changing wafer design requirements

and production needs.

EUV 3300 Source

EUV 3300 Source

Extreme Ultraviolet

Chipmaker demand for EUV light sources continues to be strong, as we believe EUV technology

is the best path toward enabling Moore’s Law and scaling of semiconductors with features 22 nm

wide or smaller. We have accelerated our rate of EUV source development, and are continuing to

increase our investment in development resources, manufacturing capacity, and field support to

fulfill EUV source demand.

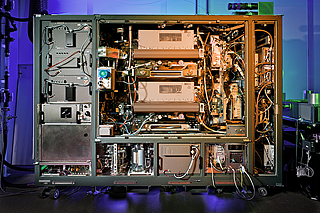

Our Laser-Produced Plasma (“LPP”) EUV light source is designed to provide scalable power that enables high volume manufacturing. Our LPP EUV source system consists of a high power, high repetition rate pulsed carbon dioxide laser, a beam delivery system, and a plasma vacuum vessel. The plasma vacuum vessel is complete with a droplet generator and collector, debris mitigation, and in-situ metrology to measure, monitor and control the system operation. The 13.5 nm wavelength is produced when a carbon dioxide laser pulse strikes small droplets of elemental tin in the plasma chamber. The laser heats the droplet of tin to the point of evaporation and super-heating to critical temperature, then the atoms shed their electrons and become highly ionized (i.e., a plasma). This causes the excited tin ions (the plasma) to emit light which is collected by a highly reflective mirror. The mirror reflects and directs the resulting 13.5 nm wavelength energy and focuses it through an aperture and into the lithography system. The plasma chamber of the EUV source is directly coupled to the scanner system’s vacuum chamber inside the scanner enclosure, requiring close coordination between the designs of our EUV source and the scanner produced by the lithography tool manufacturer. We are working closely with ASML, a lithography tool manufacturer and current customer for our EUV sources, and our key suppliers to drive execution to our power and performance roadmap. Our EUV sources are still under development and not yet capable of supporting the commercial production of integrated circuits; however, we have shipped six EUV 3100 pilot sources to date and, in 2011, we received customer acceptance and recorded revenue for three of these sources. We also received orders for our next generation EUV 3300 sources, which we expect to start shipping in 2012.